Proud to be supply chain partner of award-winning Wolsingham Sewage Treatment Works Growth Improvement Project

siris2021

on

March 5, 2022

SIRIS proud to be supply chain partner of award-winning Wolsingham Sewage Treatment Works Growth Improvement Project

The whole projects team at SIRIS is proud to have been a recognised supply chain partner in the award-winning Wolsingham Sewage Treatment Works (STW) Growth Improvement Project. Completed in 2021 during the height of the pandemic, the £6m project has been awarded Civils Project of the Year in the Constructing Excellence in the North East Awards.

Led by Tilbury Douglas (contractor) and Wood (designer) for client Northumbrian Water, the project was recognised for its use of new technology, implementation of off-site, sustainable construction methods and best-in-class collaboration between all project stakeholders

LEARN MORE

The Project

An upgrade to tackle increased flows and asset deterioration

The Sewage Treatment Works was in need of an upgrade as demand on the site had increased in line with population growth in the area, estimated at some 19%. The upgrade project had to identify solutions to the issues caused by increased flows and loads identified at the site and the related impacts on associated sewerage networks. In addition to this, further work to tackle asset deterioration and ongoing pollution incidents due to sewer overflow was to be incorporated into the project.

The design phase of the project, started in 2018, took an innovative “Off-site by Default” and DfMA (Design for Manufacture and Assembly) approach to build technology, an ethos that was mirrored throughout all phases of the project with the ongoing support of client Northumbrian Water. The Sewage Treatment Works was consequently able to be built using off-site build methodology, a ground-breaking approach within the water industry.

This method brought tangible and sizeable benefits to the project in terms of reduced costs, timelines and environmental impact; with some £1m pounds, 4 months and 34 man hours estimated to have been removed from the project initial budgets and timescales.

Northumbrian Water now plans to adopt the new off-site build approach within their AMP7 framework, a real testament to the success of the project and the collaboration of partners and supply chain throughout.

Add Your Heading Text Here

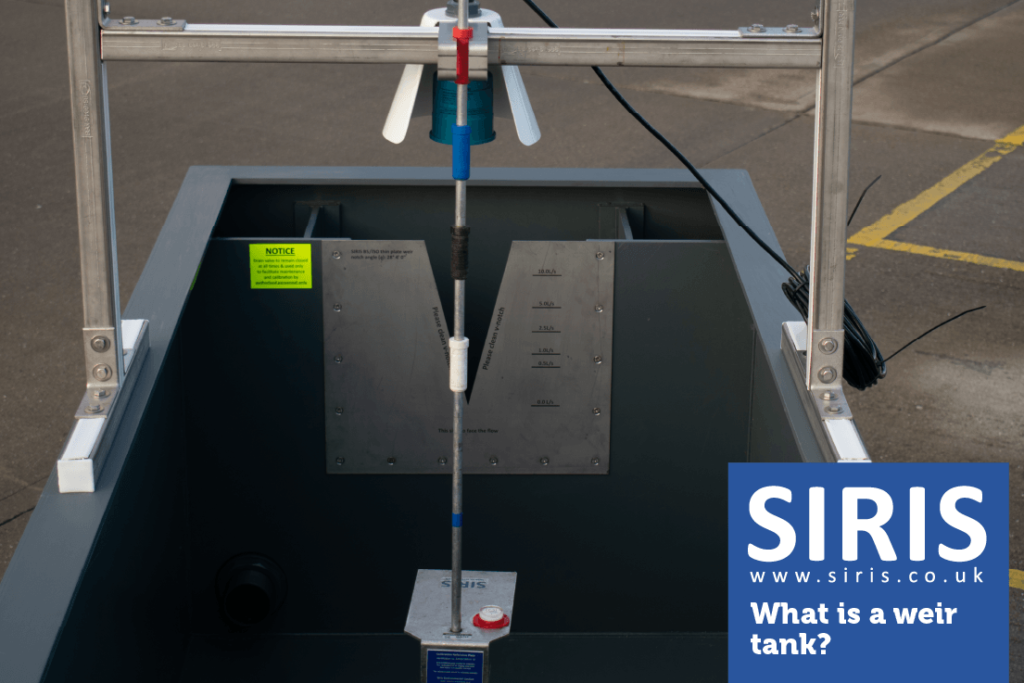

SIRIS FLOW INLET FLUME & WEIR INSTALLATION

Off-site Build Concepts

Working under the brief of design partners, Wood, SIRIS was able to develop off-site build concepts for the inlet of the works, using a prefabricated, above-ground approach. The inlet-flume design was built offsite within the SIRIS on-site factory, using non-standard GRP-reinforced, welded PVE construction materials to give the increased accuracy and sensitive tolerances expected for MCERTS certification. The materials also benefited from a service life of up to 50 years.

Transported in two sections, the inlet flume was installed readily into the SWT without problem, showing the potential for future off-site build methods for installations of this type.

“The off-site construction nature of this project represented a new approach in the water industry. With our on-site factory and engineering team, we were able to quickly integrate into the adopted working methods by providing a fully constructed inlet flume and weir system, then transported to and installed on the works site directly. Our team collaborated fearlessly with the project team to achieve all requirements and we are proud to have been involved in such an innovative development.”

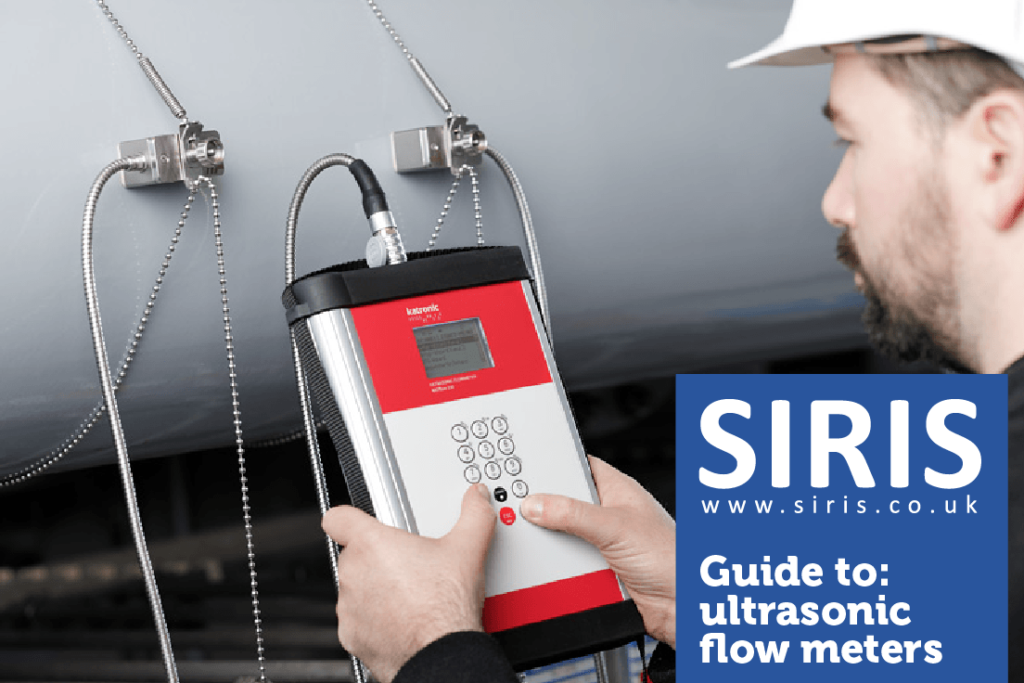

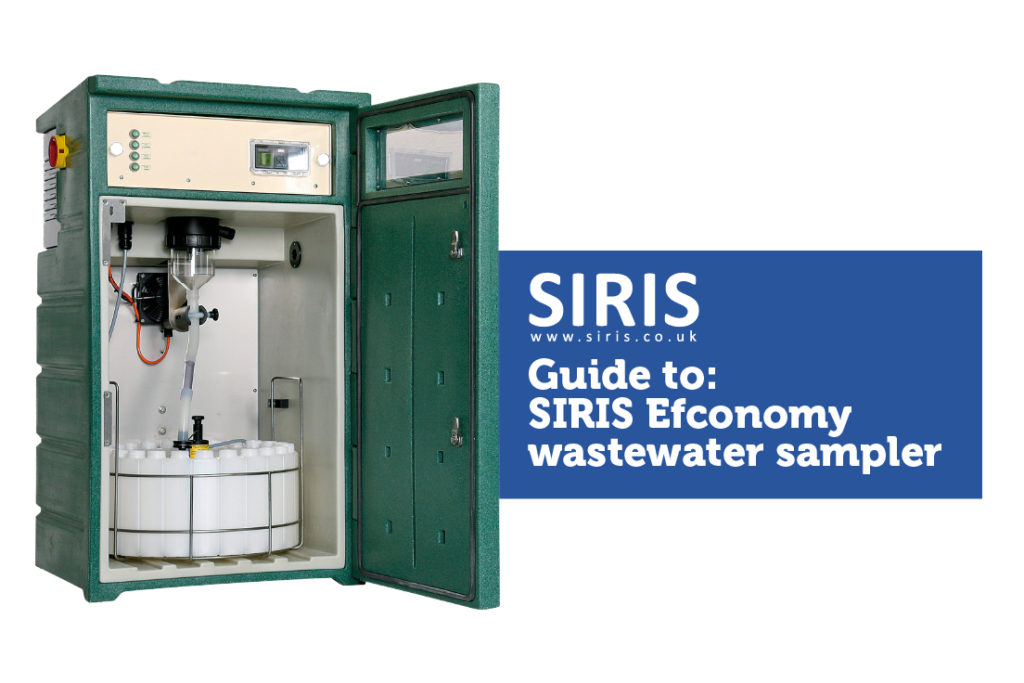

Working with varying client types, including water companies and trade customers, we design, construct and install reliable and accurate flow measurement and sampling installations for use with trade effluent and wastewater.