0191 5131313 | hello@siris.co.uk

Ensure accurate measurement across a range of flow levels

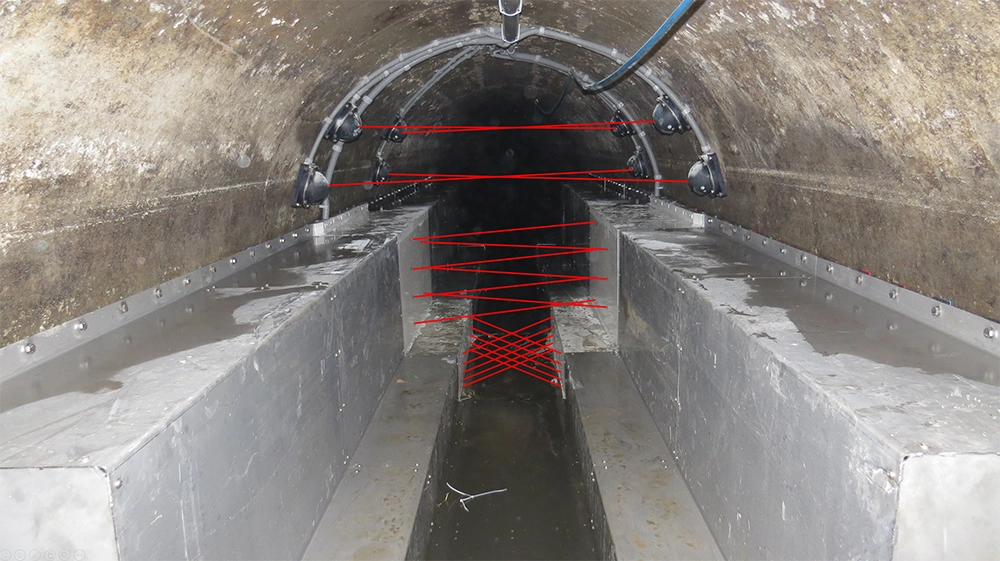

Featuring both a dry weather gutter and a rainwater channel, this flexible flow meter gives ongoing precise measurement of flow across a range of flow levels, even with small discharge quantities.

Measuring both depth and velocity, the SIRIS Ultrasonic Flow Meter for Open Channels is able to easily integrate into existing structures and operates with minimum maintenance effort.

APPLICATIONS

- Stormwater Overflow

- Combined Storm Overflow (CSO)

- Wastewater Treatment Works

- Sewer & Wastewater Flows

- Rainwater

Precise flow measurement without the need for free discharge

Using measurement of both depth and velocity, this flow meter is able to offer accurate data without the need for free discharge – making it an ideal solution on sites with limited upstream hydraulics. Its data range is suitable for both compliance and business information reporting purposes and every flow meter comes with a test certificate.

Reliable measurement results at any flow level

It is challenging to measure at extremely low flow levels with traditional flow meters. Our flow meter features an adaptable flume design, combining both a dry weather gutter and a rainwater channel, that is able to measure flow rates in both low and high flow conditions.

The rectangular shape was chosen in order to position the sensors close to each other and thus ensure a seamless, deep insight into the flow profile.

Available in a range of options

The SIRIS Ultrasonic Flow Meter for Open Channels can be used in wastewater and rainwater open channel applications, with the device available in the following 3 variations:

- Open at the top

- Closed with maintenance openings

- In pipes and ducts with a diameter >1.5m

The partially filled stationary flow measurement was designed for integration into existing structures. Not only can the channel shape be adapted to the volumes of flow produced, but various adapters are also available for connection to the existing infrastructure.

Properties

- Nominal sizes for both wet and dry installation: NW200mm to NW1200mm

- Nominal sizes for in-line construction: NW1500mm to NW3000mm

- Mounting available with suspension adapter or slide plate adapter for easy removal for maintenance work

- Wastewater flow control thanks to flapper valve

- Measurement of drainage or rainwater run-off

- Mining and process water measurements

- Local conditions such as hydraulics, surface roughness and gradient do not impact measuring accuracy

- Pre-calibrated measuring section

- Robust and reliable

- Versatile for both corporate and Local Authority use

- Works in non free-discharge conditions

- Maintenance and cleaning is easy, as the unit is open at the top or easily accessible via maintenance openings.

- Long service life – minimal wearing parts

- Fits well into most existing structures – no conversion necessary

- Wide measuring range

- Installation possible with minimal isolation flows

Learn more about the new SIRIS Ultrasonic Flow Meter for Open Channels today

Contact our team for a no-obligation discussion.

Ultrasonic transit time difference (Time of Flight)

This ultrasonic flow meter measures the velocity of a flow using acoustic waves – using the Time of Flight principle.

Imagine two boats crossing a river diagonally on the same line; one in the direction of flow and the other against the flow. The boat that moves in the direction of the current takes a much shorter time to reach the opposite bank. The same applies to ultrasonic waves. A sound wave propagates faster in the flow direction of the medium to be measured than the sound wave in the opposite direction. The travel times are measured continuously.

The transit time difference between the two ultrasonic waves is thus directly proportional to the average flow velocity.

The flow volume per time unit is the result of the average flow velocity multiplied by the respective pipe or channel cross section.

This type of acoustic flow measurement offers some advantages over other measurement methods. The measurement is largely independent of the properties of the fluid used, such as electrical conductivity, density, temperature and viscosity. The absence of moving mechanical parts reduces maintenance and there is no pressure loss due to cross-sectional narrowing. A large measuring range is one of the further advantages of this method.