Water ultrasonic flow meters mean can be a good alternative to the more expensive electromagnetic meter – provided the conditions are right. In this guide we’ll be explaining the two different types, and how and when to use them.

Types of water ultrasonic flow meters

Did you know there are two types of ultrasonic flow meter?

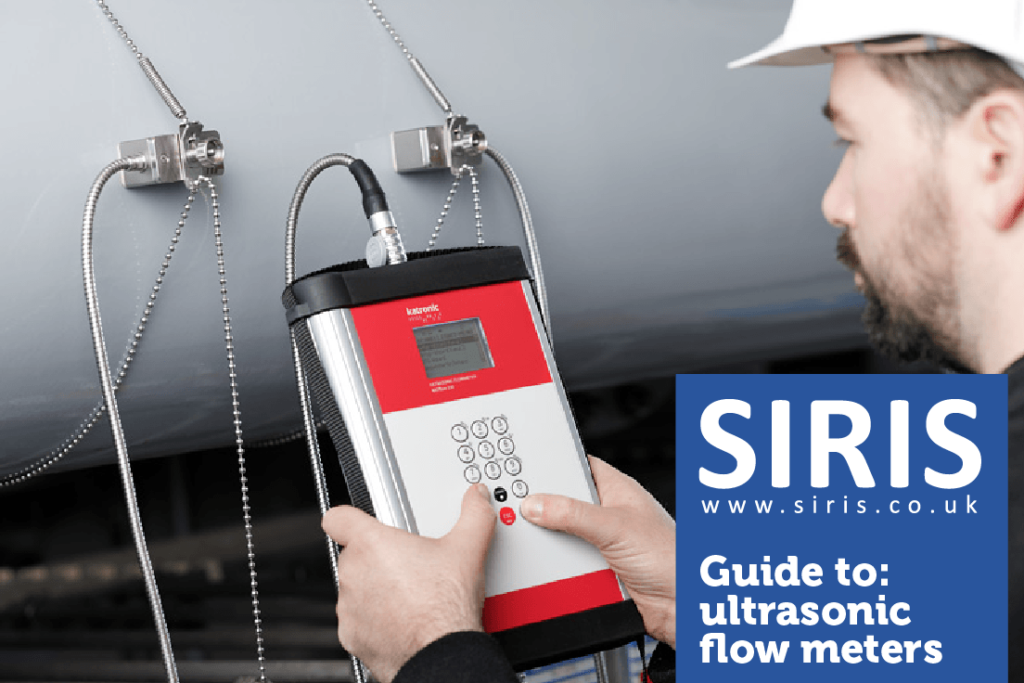

1. Clamp-on ultrasonic flow meters

Also known as “strap-on” and “time of flight”, this is usually the type people think of when talking about water ultrasonic flow meters. Clamp-on meters literally clamp on to the pipe and operate using the doppler effect.

At least two sensors (sometimes more) are positioned on the pipe across from each other. The clamp is attached tightly onto the pipe, using ultrasonic couplant gel to ensure there aren’t any air gaps between the clamp and the pipe and enhance sound transmission from the transducer. Sound bounces across and the difference is proportionate to the velocity. More sensors can be added for a greater level of accuracy.

2. Air ranging ultrasonic sensor

Another way we can measure flow using ultrasonic flow meter principles is by using a look-down air ranging level sensor. We can connect them to a flow meter to calculate flow from depth. This type can work well for open channel applications such as flumes and weirs.

Benefits of ultrasonic flow meters

- Quick installation time – we can install an ultrasonic flow meter in less than a day, providing a quick and easy measurement solution.

- No need to interrupt site activity – we can usually install this type of flow meter without the need to stop flow – this is a huge benefit for busy sites and also makes the installation process much easier (and more affordable).

- Flow to full treatment (FFT) solution – ultrasonic flow meters can be a simple and affordable solution for measuring FFT, providing the conditions are suitable.

- Diagnostics tools – many newer models include useful and accurate diagnostics, making it much easier to obtain a stable flow reading and calculate the sound speed.

- Reverse flow – like the more expensive magmeter, ultrasonic flow meters can also be used to measure reverse flow.

- Testing tool – at SIRIS we use ultrasonic flow meters as a calibration and testing tool, both on-site and at our workshop.

- Affordable solution – ultrasonic flow meters tend to be cheaper than the alternatives, so provided the site has the right conditions, they can be cost-effective solution.

Alternatives to water ultrasonic flow meters

We keep mentioning the need for the “right conditions” – and this is where the major pitfall is for this type of meter.

In order for them to work correctly and provide accurate results, there must be a long enough approach. Ideally, this is at least 10 x pipe diameters, without any bends. This is because the flow needs time to dissipate. Any churn in the water can have an impact on the accuracy of results. This is why there has historically been a reluctance within the industry to use them. However, if the conditions are right, there’s no reason why they can’t provide accurate data.

Another consideration is maintenance. The open-channel nature of this type of meter means that environmental conditions can result in it needing more maintenance than a closed-pipe alternative.

The electromagnetic flow meter (magmeter), tends to be a good alternative when an ultrasonic flow meter isn’t suitable as they require a much shorter approach (a minimum of 5 x pipe diameter).

Talk to the experts

Our team of experts have can offer advice and guidance on the best type of flow meter for your requirements. We encourage you to get in touch to find out how we can help on hello@siris.co.uk.