Ambitious new Environment Agency plans mean that wastewater treatment plants will soon need to make changes to the way they monitor flow to full treatment (FFT). But what is FFT, what are the issues and what will water companies need to do to meet the new regulations? It can be a complicated subject, so we’ve put together a guide to help you make sense of the changes.

What is flow to full treatment?

Flow to full treatment (FFT) refers to the maximum flow a wastewater treatment plant can treat.

Wastewater treatment works are built based on an estimate of flow (the volume of water going through the plant). According to the Environment Agency, water companies must design wastewater treatment works “to treat peak dry weather flow (DWT) and additional flows from light rainfall”.

The first stage of working this out is to calculate the dry weather flow (DWF), which gives an indication of the minimum volume the plant will need to treat during a period without rainfall. The DWF is then used to calculate the FFT.

A treatment works is normally designed to treat a volume of flow of three times the maximum dry weather flow (DWF). If this is flow is exceeded for example as a result of a storm event, then flows in excess of 3 x DWF are diverted to large tanks where the flow is stored until the storm subsides.

When the flow into the works reduces after the storm event has ceased and treatment capacity becomes available, the contents of the storm tanks is pumped back to the inlet to the works to pass through the treatment process.

There is quite often an emergency overflow on the works which is usually set to spill over directly to the river when the flow exceeds 6 x DWF. In addition, in the sewer system there are CSOs (combined sewer overflows) that are strategically located to spill directly to the watercourse when the system is totally overloaded and to minimise the risk of flooding homes and streets. These CSOs normally have screens installed to retain visual pollutants in the sewer system.

What are the issues?

The UK’s sewer network is outdated and the reality is that the majority of wastewater treatment works are now treating a significantly higher volume of flow than they were designed and built to accept. On a day-to-day basis this can be attributed to population increases and more homes and factories being built, however plants also need to contend with evolving unpredictable weather patterns as a result of climate change.

Enlarging existing treatment works and building new ones is no easy task – it’s a hugely expensive civil engineering project before even considering things like available space. This means that many treatment works are left with no choice but to rely on their CSOs on a regular basis, not just during heavy rainfall.

The problems arise when a wastewater treatment works’ CSOs are already full when a storm event actually arises. With nowhere else for the water to go, it has no choice but to be discharged to the UK’s water course, polluting our streams and rivers with untreated sewage.

What does the Environment Agency say?

In 2018, the Environment Agency announced its Water Industry National Environment Programme (WINEP), an ambitious set of strategic measures designed to force water companies to invest in their infrastructure in order to meet their environmental obligations between 2020 and 2025.

Water companies in England and Wales were required to submit their business plans for scrutiny by water sector economic regulator Ofwat which fed into PR19, its five-year price review and service package. The final determination of this package was announced in December 2019 and includes a detailed breakdown of requirements for each water company.

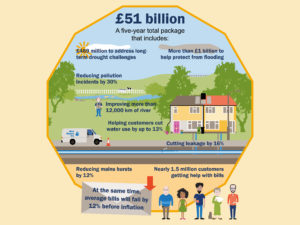

PR19 sets out a £51billion package to enable water companies to deliver their plans, including measures to reduce the number of sewage spills and protect our rivers and streams.

What does this mean for wastewater monitoring?

As part of PR19, wastewater treatment plants will be required to monitor flow to full treatment to achieve MCERTS compliance, essentially closing the loophole that allows them to regularly use CSOs as a primary part of their system.

WINEP outlines three monitoring drivers relating to this:

- U_MON3 – “Install EDM on WwTW overflows to storm tanks at those WwTW where we can’t use existing monitors to be confident that the permitted FFT setting is being complied with.”

- U_MON4 – “Install MCERTS flow monitoring as close to the overflow as practicable to record FFT at WwTW where the existing DWF MCERTS flow monitoring, or other installed flow monitoring, cannot be readily used to confirm the permitted FFT setting is being complied with when the overflow to storm tanks operates.”

- U_MON5 – “Provide MCERTS flow monitoring for the first time at WwTW where permitted DWF or maximum daily flow is greater than 50m3/d.”

From a practical perspective this means that monitoring will be more challenging and treatment plants are likely going to need to construct new flumes and means of measurement in order to get accurate results.

Our view on monitoring flow to full treatment

Every site is different and it’s essential each is assessed on its own merit so it can be adapted to meet the new regulations – that’s why we’re visiting our clients to give them an “FFT heads up” and get them ready for the changes to the way they monitor wastewater. In our view, flumes are by far the best way to measure flow to full treatment for the purposes of MCERTS and we’re already finding that many of the sites we visit have disused flumes that can be repurposed for this. However, what works for one site may not work for another and there will of course be practical considerations for each plant, such as available space.

As MCERTS inspectors, we are concerned that wastewater treatment works will opt for area velocity (AV) flow meters to measure FFT. It may be tempting to opt for these to save money, however due to the challenges in undertaking on-site calibration checks it can be very difficult to verify that they are providing accurate measurements. For this reason we strongly advise against using AV meters as a permanent solution.

To find out more about flow to full treatment and how PR19 will affect you, get in touch with our expert team.