EDM Assessment

An MCERTS inspection involves numerous steps to ensure a rigorous and accurate appraisal of the installation. During a recent site visit, our MCERTS inspectors carried out the following steps as part of their EDM inspection:

siris2021

on

February 23, 2024

An MCERTS inspection involves numerous steps to ensure a rigorous and accurate appraisal of the installation. During a recent site visit, our MCERTS inspectors carried out the following steps as part of their EDM inspection:

Maddie

on

October 2, 2023

This client was using a storm river v-notch that was measuring flow directly from the storm overspill into the …

siris2021

on

December 7, 2022

+ FREE downloadable EDM infographic!

Event Duration Monitoring (EDM) continues to be a hot topic in the water industry. In this article we’re diving in to the nitty gritty of EDM and explaining what it means for the water industry.

Find out:

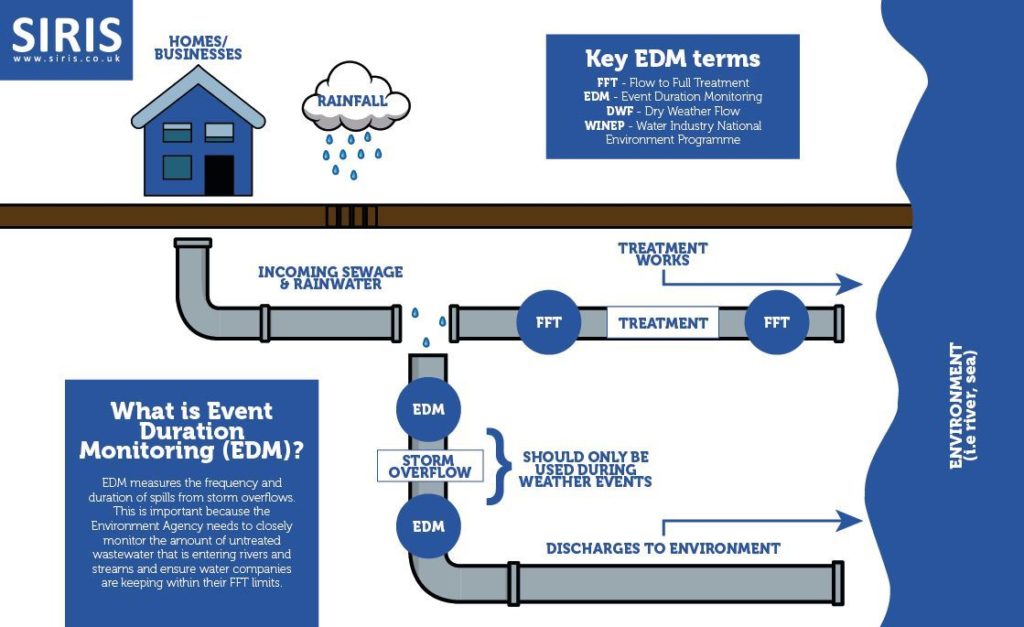

In order to explain Event Duration Monitoring (EDM), we first need to understand how water treatment works operate. Combined sewers carry wastewater from homes and businesses, however they also collect rainwater which falls onto areas like streets and roofs.

In normal conditions this water travels to a wastewater treatment works to be treated before it is discharged back to rivers and streams.

However, during a weather event (i.e. a storm or extremely heavy rainfall), water companies are permitted to use storm overflows, which are designed to store wastewater until the treatment works has capacity to treat it, or discharge the diluted wastewater back to the water course, known as a “spill”. This is essential, as otherwise untreated water would back up through the sewage system and flood homes and businesses.

EDM data measures the frequency and duration of spills from these storm overflows. This is important because the Environment Agency needs to closely monitor the amount of untreated wastewater that is entering rivers and streams and ensure water companies are keeping within their FFT limits.

In many areas the UK’s sewer system is no longer fit for purpose. In many cases sewage treatment works simply weren’t built to treat the volume of flow they now need to accept. This is a result of population increases as well as changes to weather patterns caused by climate change.

In practice, this has resulted in many sewage treatment works relying on storm overflows on a regular basis, instead of just during the storm events they were designed for. If a storm overflow is already full and a period of heavy rainfall occurs, it will not be able to cope with the additional flow and will discharge a higher volume of wastewater to the environment than it would have done if the overflow had been empty to start with.

If this goes unchecked, the UK’s rivers and streams will continue to be polluted with untreated sewage and could have serious consequences for our environment. In recent years the Environment Agency has taken steps to mitigate these risks and force water companies to monitor their use of storm overflows and invest in their infrastructure in order to meet their environmental obligations.

The Water Industry National Environment Programme (WINEP) is a programme of actions water companies are required to take to meet their statutory environmental obligations, non-statutory environmental requirements, or delivery against their statutory functions. In short, it’s the steps they need to take to help improve our environment.

The Government has challenged the UK’s water companies to create an industry that:

The Environment Agency, Department for Environment, Food & Rural Affairs (DEFRA) and Water Services Regulation Authority (OFWAT) have jointly developed an overarching process for delivering this programme in England.

WINEP aligns with OFWAT’s findings from PR19, its five-year price review and service package. Under PR19 water companies are required to begin monitoring FFT and storm events in order to achieve MCERTS compliance.

These are mentioned under two main drivers:

What does EDM have to do with FFT?

Flow to full treatment (FFT) is the maximum flow a sewage treatment works can treat. It is calculated by multiplying the dry weather flow (DWF) by three. FFT is important when carrying out EDM because it allows us to cross reference the two numbers for more accurate results.

What does EDM mean for MCERTS?

Under U_MON4, it will be a requirement for MCERTS flow monitoring to be installed to record FFT. We need to incorporate EDM to record this accurately.

Data from EDM is used in conjunction with flow data to identify whether the works is meeting its permit conditions for FFT, so it is important that the EDM data is sufficiently robust to support this assessment.

Download our free infographic to understand how Event Duration Monitoring works.

As with any flow measurement device, EDM needs to be set up and calibrated by a qualified MCERTS inspector to ensure it doesn’t trigger too early or not at all.

For support with installing an FFT or EDM system on your site, please contact our expert installations project team who will be able to offer you advice and support on choosing the right system.

siris2021

on

June 28, 2022

Download the Sitrans MAG 6000 manual.

siris2021

on

June 25, 2021

Event Duration Monitoring (EDM) helps ensure sewage treatment works (STW) are sticking to their permitted discharge limits. When combined with flow to full treatment monitoring it provides an accurate picture of where flow is going when a STW is at full capacity. In this guide we explain what it means, why it’s important and how to implement it.

When we talk about an “event” in flow measurement terms, we’re referring to an adverse weather event, typically a storm, that increases the amount of flow going through a sewage treatment works.

In simple terms, Event Duration Monitoring allows a treatment works to monitor whether or not an event is happening, and how long it lasts.

This is important because an STW has a maximum limit it is permitted to treat, known as flow to full treatment (FFT). This is based on a calculation, normally three times the maximum dry weather flow (DWF). Anything exceeding this amount when storm event occurs is permitted to overflow to storm management systems, or be discharged to a river.

The problem arises when a works discharges to storm management before its maximum limit is reached, as this is a breach of its permit and illegal.

The Environment Agency’s U_MON3 driver requires water companies to install EDM monitoring by 2025, and more recently the Government announced further measures to ensure STWs are not relying on storm overflows outside of storm events.

In 2018, the Environment Agency announced a series of measures designed to better monitor flow to full treatment, which included mention of Event Duration Monitoring:

“Install EDM on WwTW overflows to storm tanks at those WwTW where we can’t use existing monitors to be confident that the permitted FFT setting is being complied with.” U_MON3 Driver

In a recent report, the EA said it had installed 12,000 monitors by the end of 2020, with installations on remaining sites expected to be completed by 2023.

The EA says EDM will give them an accurate picture of how water companies are using their storm overflows and allow them to identify where improvements can be made, take enforcement action where necessary, and ultimately improve water quality.

The EDM device is usually situated immediately upstream of the FFT meter so if any excess flow goes into stream it can record it.

Traditionally, the most common way of collecting Event Duration Monitoring data is by using a flow measurement device with probes. However, as they are fundamentally contact devices this can cause problems if the probes become damaged or dirty. Careful installation is essential for this type of device because it can be very difficult to reference them against the low point of the weir.

A better solution is a non-contact device such as an ultrasonic or radar, installed on a fixed robust bracket that includes a calibration reference point and correctly referenced against the spill height. With care, this should be able to be undertaken within +/- 2mm.

As with any flow measurement device, EDM needs to be set up and calibrated by a qualified MCERTS inspector to ensure it doesn’t trigger too early or not at all.

To find out more about EDM and how we can help, get in touch with our friendly and professional team.

Additional resources:

siris2021

on

March 31, 2020

The CSA Group*, the provider of the Environment Agency’s MCERTS scheme, recently released Bulletin 27, an update on how area velocity (AV) flow measurement systems should be installed and used.

The use of AV technology can cause confusion – particularly as new rules on flow to full treatment (FFT) are due to come into force. Our guide aims to help you make a more informed decision when choosing your wastewater system.

Area velocity (AV) flow meters are used for measuring flow without a flume or weir. They operate on the “area velocity principle” – a probe is inserted into the water and continuously transmits ultrasonic pulses. when particles pass through it registers the shift in area velocity and uses this to calculate the flow.

AV meters are popular because they are quick and easy to install – simply fitting them to a pipe or open-channel. They also tend to be more affordable than alternatives, such as electromagnetic flow meters.

However, a downside to AV meters is that it is difficult during MCERTS inspections to verify the accuracy of the results they are producing. This means that although they may seem like a cost-effective solutions, in reality they can often end up costing more in the long run. As MCERTS inspectors we would only recommend AV meters over other meters in certain situations, such as a temporary option or where other solutions aren’t viable.

Soon, the Environment Agency will require wastewater treatment works to comply with new regulations in the way they measure flow to full treatment (FFT). This may mean that many sites will opt for AV meters as a quick and affordable solution to meet requirements, but it is important that you make yourself aware of potential limitations before committing. In all instances you should seek the advice of MCERTS-qualified advisors.

The CSA Group occasionally shares updates and additional guidance relating to the existing Environment Agency MCERTS guidelines, known as bulletins.

Bulletin 27 – “Installation and use of area-velocity flowmeters in free surface flows.” is the most recent update and provides guidance on how area velocity flow meters should be used in order to pass MCERTS inspections.

The key things it covers are:

Bulletin 27 clarifies some areas of concern raised on how the accuracy of area velocity flow meters can be verified.

One of the key things it confirms is that there must be a “defined measurement section”. This is described as:

“a straight, stable length of channel or pipe with a constant cross section and with a length which is sufficient to create a fully developed flow profile at all expected flowrates.

Note: This will normally require at least 20 channel widths/pipe diameters upstream and 5 channel widths/pipe diameters downstream of the flowmeter.”

The additional note is important – although it acts as a recommendation it gives important guidance as to how we can accurately verify the results the area velocity flow meter provides. Bulletin 27 also explains that if these conditions can’t be met the site can still be MCERTS certified, so long as the inspector “is satisfied that that the flow measurement uncertainty conforms to the MCERTS requirements at all expected flow rates”.

Another important issue addressed is maintenance. Area velocity flow meters measure the area of the channel – and that means that any build-up of material within the channel will skew the results. It states that “the sensors and the measurement section shall be kept free from sediment and other fouling material.” In other words, the channel needs to be kept cleaned and well-maintained in order to confirm accuracy of results.

Area velocity technology should be carefully considered as a long term solution, weighing up issues of potential accuracy and verification before focusing on cost and speed of installation. Despite the relatively low initial outlay for an AV meter, inaccurate results and the issues presented by them over a long period could ultimately cost businesses and water companies more money. Electromagnetic flow meters or flumes can remove the typical issues found with AV meters and their data accuracy and, even though more costly for initial installation, can prove more cost-effective in the longer term.

It is encouraging to see further clarification on the use of AV meters from CSA Group and we believe that if these guidelines are followed – particularly the recommended installation location – then it will go some way in improving the accuracy of this technology.

To discuss your requirements, get in touch with our friendly team on 0191 5131313, or email hello@siris.co.uk.

*Confused about the role of the CSA Group? Read our guide to the key wastewater industry players.

siris2021

on

December 19, 2019

As producers of trade effluent, food and beverage manufacturers are required to take part in the Environment Agency’s MCERTS scheme. However, many manufacturers simply don’t realise that they could save money by investing in a new wastewaster monitoring system. We worked with our supplier Pulsar Process Measurement to ensure MCERTS compliance for food manufacturer Premier Foods, in Newport.

The site’s existing wastewater monitoring system wasn’t fit for purpose – an older weir tank was installed but it was undersized for the capacity required and was costing the food manufacturer money and making it difficult for them to measure accurately.

We assessed the site and worked with Pulsar and the client to understand the options available to them. We recommended installing a much larger weir tank – utilising space the factory had close to the existing tank.

A larger tank results in smoother, more tranquil flow which allows for greater accuracy in measurement.

As accuracy was such a key consideration for this site, we designed and installed the system to work alongside Pulsar’s DUET flow meter. Unlike a standard ultrasonic flow meter, which operates using a single transducer, the DUET’s unique design utilises two transducers to provide highly accurate results.

By installing a fully-compliant system that was tailored to the client’s requirements, we were able to help the company make substantial savings.

Discharging more or less trade effluent than is stipulated in the conditions of a company’s consent to discharge permit can prove costly.

A food manufacturer discharging too much trade effluent can result in fines from the Environment Agency – and the company will also be required to apply for a new permit at a further cost. However, discharging less than expected also has cost implications as the company will be paying to discharge more than it actually is!

Correct and accurate monitoring that meets MCERTS requirements and uses MCERTS-certified equipment is the only way to ensure a manufacturer is paying the correct amount.

We offer an MCERTS guarantee, meaning that any system we design, install and maintain will be fully MCERTS-compliant. MCERTS compliance for a food manufacturer is vital, as it ensures that their system is performing at a high level of accuracy and providing cost-effective results, while remaining within the limits of their consent to discharge permit.

siris2021

on

November 26, 2019

As well as providing MCERTS inspection services, we also stock a range of MCERTS approved products, including flow meters and wastewater samplers.

But what are MCERTS approved products, and why do you still need MCERTS inspections if you already use certified products as part of your wastewater monitoring system? Our guide answers these questions.

A quick refresher if you’re new to the world of MCERTS:

MCERTS refers to the Environment Agency’s Monitoring Certification Scheme (MCERTS), which provides a framework of standards for the safe monitoring of liquid flow, such as trade or sewage effluent. Compliance with MCERTS ensures that everybody involved in the measurement of liquid flow is working towards the same standards and is providing accurate emissions information to the Environment Agency. The regulation covers areas such as product and personnel certification, as well as the quality of inspections.

If you want to learn more about MCERTS, check out some of our other guides.

The CSA Group is responsible for certification standards across a range of areas and operate internationally across a wealth of countries. Within the UK, among many other areas of certification, it delivers the MCERTS scheme, under the SIRA name.

According to CSA, the MCERTS product certification scheme provides the mechanism for the certification of products according to Environment Agency performance standards, which are based on relevant CEN, ISO and national standards.

MCERTS is a mark of quality, giving consumers the confidence that the products they are using are fully compliant with Environment Agency standards.

Ensuring the equipment you are using is MCERTS certified is just one part of complying with the Environment Agency’s standards. In fact, MCERTS covers everything from equipment performance standards, the level your staff must be qualified to and accreditations of the people carrying out your site inspections.

Your wastewater monitoring equipment must meet the required standard, however it is still your responsibility to choose an appropriate monitoring system and ensure it is installed correctly. Sites with consent to discharge permits are required to host regular inspections (at least every five years) to make sure their monitoring system is performing within the stipulations of their permit.

As qualified MCERTS inspectors, we can take responsibility for this entire process – from specifying a flow measurement system that best suits your requirements and is compliant with your consent to discharge permit and installing it to Environment Agency standards, to carrying out regular site inspections to ensure ongoing compliance.

We know the world of MCERTS can be confusing – which is why we pride ourselves on offering a “one-stop-shop” solution to our customers. To find out how we can help you, get in touch with our friendly team on 0191 5131313 or email hello@siris.co.uk

siris2021

on

November 8, 2019

If you’re new to the world of wastewater monitoring, it’s likely one of the first terms you have come across is “trade effluent”. But what is it and what does it mean for your business? We’ve put together a quick guide to explain.

As a broad term, effluent includes any liquid waste entering a water body such as rivers or the sea. Most commonly we think of effluent as being sewage, however this is not always the case. Sewage is a form of effluent but not all effluent is sewage!

Trade effluent is wastewater being produced by a business during the course of industrial activity which is potentially harmful to the environment. It can be confusing as not all wastewater produced by businesses is classed as “trade effluent”.

Typically, any wastewater produced by factories, chemical processing and engineering plants, car washes, laundrettes and swimming pools counts, whereas that produced by hairdressers, restaurants/takeaways/pubs/hotels, medical practices, residential homes (e.g. care homes), grocers and office buildings, doesn’t. This is because water companies don’t consider its content high risk enough to complicate processing at water treatment works.

It is illegal to discharge trade effluent to a public sewer without consent from your water authority. This is because water companies need to know about factors such as its strength, content and volume to make sure their treatment plants can process it correctly, as well as manage potential risks to people or the environment.

To find out more about consent to discharge and applying for a permit, read our guide. You will also be required to monitor your effluent under the government’s MCERTS scheme.

We can help you understand your trade effluent requirements and advise you on your next steps. Get in touch with our team of MCERTS experts today.

siris2021

on

August 23, 2019

If you’ve been researching your effluent discharge permit requirements, you’ve probably come across the terms “SIRA Test and Certification”, CSA Group, Environment Agency and SCS, among others. But what are all of these terms and what do they have to do with MCERTS?

SIRA originally started within the British optics industry in 1918, offering services within scientific research. The full company name is SIRA Certification Service (or SCS for short) but most of those in the industry simply reference SIRA.

In 2009, SIRA was acquired by the CSA Group and, in May 2015 the group merged SIRA with another company to form CSA Group Testing UK Ltd.

SIRA does still exist and is the EU notified body (No. 0518) related to ATEX* activities, as well as IECEx CB & ExTL for IECEx approvals and covers, among other certifications, MCERTS. So, you can think of SIRA as the parent company that manages and issues MCERTS accreditation, but SIRA itself is owned and managed by the CSA Group. You will still see the SIRA name used widely within the industry and the CSA Group readily states that many of its client companies still request SIRA certification marks and logos in order to use them within their product labelling and literature.

*ATEX stands for “atmosphères explosibles”, which is an EU Directive covering “equipment and protective systems intended for use in potentially explosive atmospheres.”

The CSA Group (which was initially known as the Canadian Standards Association) is responsible for certification standards across a range of areas and operate internationally across a wealth of countries. Within the UK, among many other areas of certification, it is the provider of the MCERTS environmental certification scheme, under the SIRA name.

To complicate things even a little more (!) MCERTS is actually the Environment Agency’s Monitoring Certification Scheme for equipment, personnel and organisations, but the CSA Group is the body approved to manage the MCERTS scheme, through its UKAS-accredited SIRA arm, and according to the ISO/IEC 17000 series of conformity assessment standards.

MCERTS is a UK scheme that ensures compliance with the EU directives regulating emissions, monitoring data, equipment and employees. It provides a robust framework to ensure consistent and safe standards for monitoring liquid flow, such as commercial or water authority effluent. MCERTS compliance goes a long way to ensuring that there is consistency of standards and accuracy of information to the Environment agency with regards to the measurement and sampling of this liquid flow.

You can view the status of your certification from SIRA, including MCERTS through its Certificate Database that shows whether a certificate is still current or has been withdrawn or suspended.

MCERTS covers areas such as product and personnel certification, as well as the quality of inspections.

Briefly, the MCERTS scheme covers a range of monitoring, sampling and inspection activities including:

You can read full information about MCERTS and how SIRIS can help ensure your site’s compliance with the scheme here.

Since 1996, the Environment Agency has been the UK authority responsible for protecting and improving the environment of England. It is both a licensing and a regulatory authority, issuing permits within specified thresholds and monitoring requirements, and also inspecting and regulating the conditions of these permits. It has the power to prosecute those who fail to comply with the conditions of their Environmental Permits.

If you would like to know more about the Environment Agency’s standards, permits and conditions, or to view more information about the MCERTS scheme, or to download the Environment Agency’s performance standards and requirements, please view EA Mcerts Monitoring Emissions.