0191 5131313 | hello@siris.co.uk

CASE STUDY: FLOW SYSTEMS INSTALLED IN FOOD FACTORY

michael mc

on

March 13, 2023

CASE STUDY

CASE STUDY: FLOW SYSTEMS INSTALLED IN FOOD FACTORY

The Client Needs

Our food factory client required two new flow system installations for their site in South West England.

Work Completed

The first install was for a full new flow system, comprising of:

– Flow meter

– Ultrasonic transducer and bracket

– A new primary device of a rectangular weir on a SIRIS carrier board (suitable for flows up to 50 l/s

The second install was also for a flow system as per the above specification but did not require a new primary device as the current one met MCERTS standards.

The Outcome

The client now has confidence in a system that will not only meet their internal reporting and monitoring needs but will also ensure they meet compliance standards for MCERTS inspections and any associated audits.

Before

After

FLUMES IN FOCUS

siris2021

on

February 27, 2023

PRODUCTS FOCUS

FLUMES IN FOCUS FOR SIRIS

At SIRIS we are driven by innovation and continuous improvement in our products and processes. Flumes are no exception, with this component being an integral part of the SIRIS product portfolio and many flow monitoring system solutions.

Flume Innovations

Our team has been listening hard to the ongoing needs of clients and modern-day flume requirements and we have consequently implemented two innovations to our range of flumes.

A New, Deeper Flume Option

During a routine post-installation verification check, one of our experienced project engineers quickly identified issues within this flow meter installation. It rapidly became apparent that the third-party contractor had not installed the meter correctly, meaning that incorrect measurements were pulling through to the data feed.

Our engineer was able to recognise that the Sensorprom (the part of the flow meter sensor that carries the unit calibration value) had not been installed correctly and had defaulted to factory settings. This included the incorrect bore size, the calibration (cal) factor and the excitation value.

During our initial response our engineer was able to adjust and reset the flow meter to the unique original Sensorprom characteristics. On adjustment the meter significantly changed its flow reading and this was checked against a secondary time of flight reference.

Boxed Flumes

We now offer our flumes in protective boxed packaging. This means that they are better protected against damage and the elements, as well as being kept secure during transit.

The hardwearing purpose-built boxes protect the flumes against knocks and scratches and even have a built-in tarpaulin to allow safe storage on site in wet weather conditions.

Our SIRIS boxed flumes are available in a range of sizes and are in stock for immediate delivery.

We are encouraging our customers to return the boxes to SIRIS to be re-used and help reduce our environmental footprint. Instructions explaining how to arrange the return of the box are included in all shipments.

Lee, Project Engineer

“We are always seeking to innovate and respond to our client needs. These two new additions to our flumes range allow us to further improve our service offering to the market. We are proud of our team here – there is a natural curiosity to investigate possible solutions and find new answers to existing challenges. This is what helps us to stay at the forefront of our industry.”

Require flumes or full flow monitoring system?

Our team has the solution for you. Talk to us today.

CASE STUDY: FLOW METER RECALIBRATION

michael mc

on

February 14, 2023

CASE STUDY

CASE STUDY: FLOW METER RECALIBRATION

An end user client was experiencing issues with data accuracy after the installation of a flow meter by a third-party contractor. Our team was able to swiftly identify and adjust set-up to ensure the data they received was correct.

The Client Needs

It was identified that an end user dairy producer was experiencing issues with accuracy of data outputs from their newly-installed electromagnetic flow meter. It was important that the cause was identified and rectified so that their data was correct, particularly as this was used for charging purposes.

Our Response

During a routine post-installation verification check, one of our experienced project engineers quickly identified issues within this flow meter installation. It rapidly became apparent that the third-party contractor had not installed the meter correctly, meaning that incorrect measurements were pulling through to the data feed.

Our engineer was able to recognise that the Sensorprom (the part of the flow meter sensor that carries the unit calibration value) had not been installed correctly and had defaulted to factory settings. This included the incorrect bore size, the calibration (cal) factor and the excitation value.

During our initial response our engineer was able to adjust and reset the flow meter to the unique original Sensorprom characteristics. On adjustment the meter significantly changed its flow reading and this was checked against a secondary time of flight reference.

The Outcome

The end user now has confidence that their flow data being recorded and subsequently billed against is correct.

Lee, Project Engineer

“It is critical that any flow meter installation is carried out in line with the manufacturer’s recommendations and industry best practice, and that an independent verification process takes place. Flow monitoring systems are complex and in the case of electromagnetic flow meters there are often issues that would only be obvious to an experienced user. We would advise any end users using contractors to carry out appropriate due diligence on the experience and knowledge of a potential flow monitoring system installer. We are always here to provide advice and support.”

CASE STUDY: CHEMICAL INGREDIENTS MANUFACTURER TRADE EFFLUENT MONITORING SYSTEM

michael mc

on

February 14, 2023

CASE STUDY

TRADE EFFLUENT MONITORING SYSTEM

Requirements

Our client, a chemical ingredients manufacturer, recently required a trade effluent flow & monitoring system in order to comply fully with regulatory discharge requirements.

Specification & Installation

To specify the correct system our team confirmed detailed information unique to the site. This included land layout and location, flow volumes and discharge limits, the nature of discharge and upstream hydraulic levels. This information is critical and helps ensure the “correct” system is specified in the first instance.

Our from-scratch solution included:

• Full flow monitoring system comprising: small weir tank with 28º4′ V-Notch thin plate weir and ultrasonic open channel flow meter

• Partech 7300w2 ph and temperature monitor

• Point orange cloud-based data logger

• SIRIS 4-bottle vacuum sampler

Production is now complete and the entire system is ready to ship to the customer. Once installed on site by the client, SIRIS engineers can attend to check the calibration and ensure everything is operating correctly. This would include site calibration of all the instrumentation.

Case Study: Finding the right flow monitoring solution for a National Park holiday resort

siris2021

on

December 20, 2022

CASE STUDY

Flow Monitoring Solution for a National Park holiday resort

Our partner commercial drainage specialist Metro Mechanical asked for our help to find a suitable flow monitoring set-up that preserved the natural beauty of a unique National Park setting and provided the end customer with the flow data they needed.

The Challenge

The end customer was a holiday resort in a scenic location within the Lake District National Park. They process high volumes of waste and are charged by volume by the water company, however they didn’t have any way of measuring the amount they were using.

The project was further complicated by a lack of mains power to the remote site.

Alistair, SIRIS Projects

“The client needed a solution that not only provided accurate and reliable data provision, but was sympathetic to the aesthetics of the surrounding environment.”

The Solution

We designed and installed an electromagnetic battery-powered solution, which allowed the customer to monitor its flow data via the cloud without any power. Metro Mechanical built a chamber that allowed access to the flow meter, with a lid enabling it to blend into its scenic surroundings and avoid impacting the landscape.

The Result

We were able to provide a solution that not only ensured effective flow monitoring but also ensured the preservation of the natural beauty of the National Park setting.

Require Flow Monitoring?

Do you have a flow meter monitoring requirement? Contact us to understand how you can quickly get a solution to your project.

Case Study: Flow Meter Hire

siris2021

on

December 20, 2022

CASE STUDY

Flow Meter Hire

We helped this contractor ensure their project was designed and installed within the correct parameters for the rate of flow within the sewage treatment works.

The Challenge

A UK contractor delivering a project at a sewage treatment works needed to better understand the rate of flow into the works, in order to ensure installations were designed and fitted to the right size and specification.

The situation did not require a permanent installation, but a reliable solution that would give accurate data on the rate of flow into the sewage treatment works.

Alistair, SIRIS Projects

“It was vital that this client was able to build an accurate picture of the flow rate so that they could specify the correct works and installation for the end customer. We worked quickly to bring them a solution that was not only reliable, but also delivered the data in a way that was easily understood and decisions could be made.”

The Solution

Our team worked with the contractor to understand requirements before proposing and installing a solution that comprised of time-of-flight meters on three lines within the works. Pre-work included checking return pump flows to ensure adequate conditions within the pipe for the installation of the meters. Adverse weather conditions meant that the sensors had to be adequately protected from the elements. The meters were then calibrated and left to collect data over a number of weeks in order to build a reliable data picture of the rate of flow. Each flow meter was connected to data loggers, which then sent measurements to the cloud.

The Result

Key to success of this project was the client’s ability to view the data visually. All SIRIS flow meter hires include remote access from any device to the data, which is not only available in its raw format, but also in pre-set and standardised visual formats that are easily understood by most stakeholders.

The contractor was able to accurately understand the rate of flow throughout the works and therefore specify and install the correct solution for the end client.

Flow Meter Hire?

Do you have a flow meter hire requirement? Contact us to understand how you can quickly get a solution to your project.

EDM: Event Duration Monitoring 101

siris2021

on

December 7, 2022

LEARN MORE ABOUT:

Event Duration Monitoring 101

+ FREE downloadable EDM infographic!

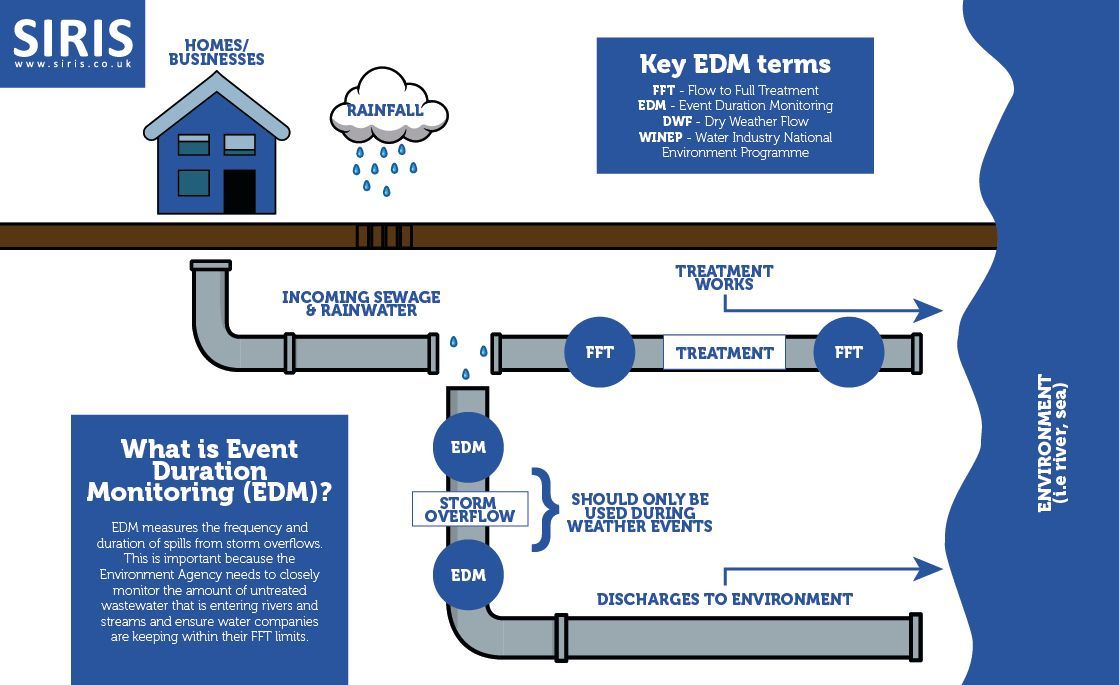

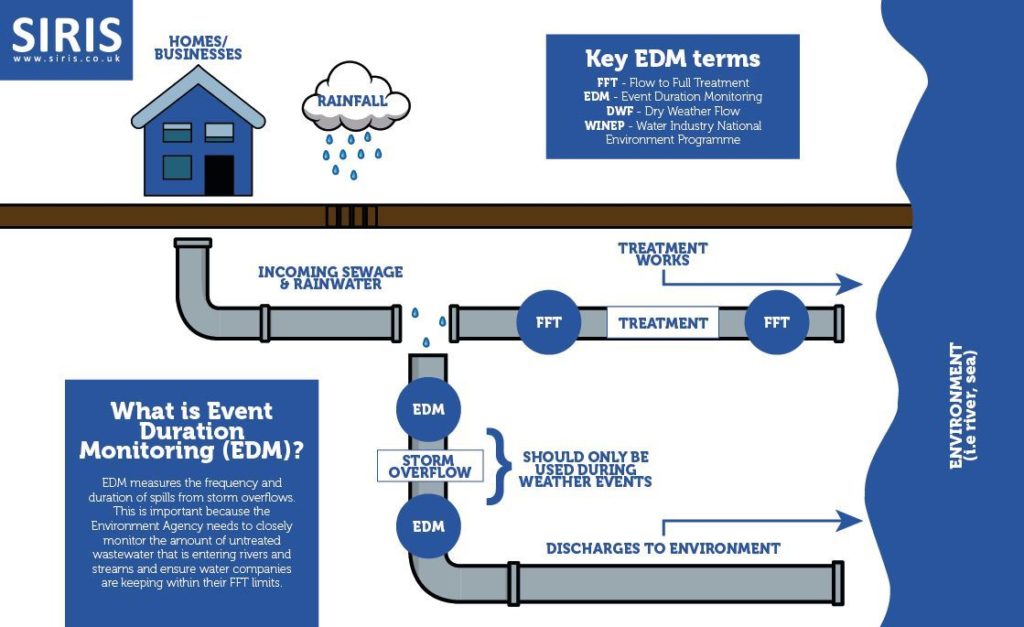

Event Duration Monitoring (EDM) continues to be a hot topic in the water industry. In this article we’re diving in to the nitty gritty of EDM and explaining what it means for the water industry.

Find out:

- What is EDM?

- Why is everyone talking about it?

- What WINEP is

- What EDM means for FFT and MCERTS

- How we can help

- Plus download our free EDM infographic.

What is Event Duration Monitoring (EDM)?

In order to explain Event Duration Monitoring (EDM), we first need to understand how water treatment works operate. Combined sewers carry wastewater from homes and businesses, however they also collect rainwater which falls onto areas like streets and roofs.

In normal conditions this water travels to a wastewater treatment works to be treated before it is discharged back to rivers and streams.

However, during a weather event (i.e. a storm or extremely heavy rainfall), water companies are permitted to use storm overflows, which are designed to store wastewater until the treatment works has capacity to treat it, or discharge the diluted wastewater back to the water course, known as a “spill”. This is essential, as otherwise untreated water would back up through the sewage system and flood homes and businesses.

EDM data measures the frequency and duration of spills from these storm overflows. This is important because the Environment Agency needs to closely monitor the amount of untreated wastewater that is entering rivers and streams and ensure water companies are keeping within their FFT limits.

Why is everyone talking about EDM?

In many areas the UK’s sewer system is no longer fit for purpose. In many cases sewage treatment works simply weren’t built to treat the volume of flow they now need to accept. This is a result of population increases as well as changes to weather patterns caused by climate change.

In practice, this has resulted in many sewage treatment works relying on storm overflows on a regular basis, instead of just during the storm events they were designed for. If a storm overflow is already full and a period of heavy rainfall occurs, it will not be able to cope with the additional flow and will discharge a higher volume of wastewater to the environment than it would have done if the overflow had been empty to start with.

If this goes unchecked, the UK’s rivers and streams will continue to be polluted with untreated sewage and could have serious consequences for our environment. In recent years the Environment Agency has taken steps to mitigate these risks and force water companies to monitor their use of storm overflows and invest in their infrastructure in order to meet their environmental obligations.

WINEP

The Water Industry National Environment Programme (WINEP) is a programme of actions water companies are required to take to meet their statutory environmental obligations, non-statutory environmental requirements, or delivery against their statutory functions. In short, it’s the steps they need to take to help improve our environment.

The Government has challenged the UK’s water companies to create an industry that:

- “provides resilient, safe, and affordable water supply and wastewater service for today’s users and future generations

- provides a thriving natural environment with increased environmental value, clean rivers and a sustainable eco-system

- consumers trust and delivers an excellent day to day service, support for vulnerable consumers and acts in the long-term interests of society and the environment”

The Environment Agency, Department for Environment, Food & Rural Affairs (DEFRA) and Water Services Regulation Authority (OFWAT) have jointly developed an overarching process for delivering this programme in England.

WINEP aligns with OFWAT’s findings from PR19, its five-year price review and service package. Under PR19 water companies are required to begin monitoring FFT and storm events in order to achieve MCERTS compliance.

These are mentioned under two main drivers:

- U_MON3

Install EDM on WwTW overflows to storm management systems at WwTW and at last in line overflows at sewage pumping stations. - U_MON4

Install MCERTS flow monitoring as close to the overflow as practicable to record FFT at WwTW where the existing DWF MCERTS flow monitoring, or other installed flow monitoring, cannot be readily used to confirm the permitted FFT setting is being complied with when the overflow to the storm management system operates.

What does EDM have to do with FFT?

Flow to full treatment (FFT) is the maximum flow a sewage treatment works can treat. It is calculated by multiplying the dry weather flow (DWF) by three. FFT is important when carrying out EDM because it allows us to cross reference the two numbers for more accurate results.

What does EDM mean for MCERTS?

Under U_MON4, it will be a requirement for MCERTS flow monitoring to be installed to record FFT. We need to incorporate EDM to record this accurately.

Data from EDM is used in conjunction with flow data to identify whether the works is meeting its permit conditions for FFT, so it is important that the EDM data is sufficiently robust to support this assessment.

Infographic

Learn how EDM works

Download our free infographic to understand how Event Duration Monitoring works.

How can SIRIS help?

As with any flow measurement device, EDM needs to be set up and calibrated by a qualified MCERTS inspector to ensure it doesn’t trigger too early or not at all.

For support with installing an FFT or EDM system on your site, please contact our expert installations project team who will be able to offer you advice and support on choosing the right system.

Which wastewater analysing equipment is right for me?

siris2021

on

November 9, 2022

LEARN MORE ABOUT:

Which wastewater analysing equipment is right for me?

Our guide to wastewater analytics.

The majority of businesses producing wastewater are required to carry out wastewater sampling to comply with their consent to discharge permit requirements. In most cases, an automatic effluent sampler is the most suitable option for accurately and reliably meeting sampling requirements. However, for some businesses additional analytical equipment can be helpful.

In this guide we’ll explain:

- The main types of wastewater analysing equipment

- How to choose the right equipment for your business

Wastewater samplers

Wastewater samplers are designed to automatically collect samples of wastewater and trade effluent via a hose at regular pre-programmed intervals. A thermoplastic unit keeps the samples at the optimum temperature. This is important as effluent contains Biological Oxygen Demand (BOD), which must be kept cold in order to be effectively measured. Automatic samplers are connected to a site’s wider flow measurement system and can function either independently or as part of an existing PLC/SCADA system.

There are two types of wastewater sampler – vacuum and in-line (guillotine). The version you need will depend on whether you have an open channel or closed pipe application.

Photometers & spectrophotometers

Businesses with larger sites or that require more detailed information on their wastewater status may benefit from additional analytical equipment.

Hand-held photometers and spectrophotometers offer a convenient way of conducting instant wastewater sampling analysis. They offer a range of testing options and pre-programmed tests, giving an immediate picture of wastewater analyte levels and understand how well you are meeting parameters within your consent to discharge. Results are instant which means you can check vital information on compliance and potential trade effluent costs without waiting for lab results.

This can be beneficial because factors such as products changes, new on-site processes and seasonal temperature variations can all have an impact on the quality and analyte levels within trade effluent. Having a portable device on-site is a quick and simple way to check analyte levels without the need for specialist laboratory equipment.

In-line monitors

In-line monitors are a good option for businesses that need to track specific analytes such as pH and turbidity in their wastewater, and provide a more affordable option than a photometer or spectrophotometer.

Depending on the nature of the business, you may be required to test the following physical properties by MCERTS:

- Temperature

- pH

- Salinity

- Turbidity

- Colour/odour

At SIRIS, we supply the Partech 7300w² Monitor, which is a great option for monitoring a range of values, comfortably accommodating up to eight sensors, with additional sensors a possibility depending on site capacity.

The 7300w² Monitor can be paired with sensors monitoring pH, temperature and turbidity, so it’s possible to pick and choose as required.

Partech partner

Our status as a Partech sales and service partner allows us to offer a range of analytical measurement devices, enhancing our service offering and giving our customers additional wastewater monitoring options. We can supply, install and maintain a range of Partech products and offer ongoing support to our customers.

Wastewater analysis data monitoring

In addition to on-site sampling and analytical equipment, many of our customers also opt to add on a Cloud-based data monitoring to their wastewater analysis package. Having the ability to track your site’s effluent discharge provides peace of mind and confidence that you are staying within your limits – as well as allowing you to see if you are paying too much.

Our data monitoring system uses a data visualisation suite paired with a specialist remote telemetry unit (RTU) to provide businesses with 24/7 access to their data, from anywhere with an internet connection.

How can you make sure you choose the right wastewater analysing equipment?

Wastewater analysis is a highly complex and confusing area, and it can be difficult to navigate the various options available. It’s essential you consult experts to ensure the system you choose is fit for purpose and cost-effective. Choosing the wrong products can be a costly mistake and there are a number of factors which can push the price up further, including poor installation practice and a lack of expertise from your supplier.

Ultimately, a correctly installed system supported by a team of experts is the only way to be sure you are getting a cost-effective and reliable system.

In addition to our range of MCERTS-approved wastewater samplers and analytical measurement tools, at SIRIS we offer comprehensive support and guidance to help you choose the best option for your site.

MCERTS flow measurement: Why it’s essential to consult the experts

siris2021

on

September 7, 2022

LEARN MORE ABOUT:

MCERTS flow measurement

Why it’s essential to consult the experts

We often get calls from customers requesting quotes for part of a flow system – and they’re often surprised when we explain that it isn’t as simple as just selling them a flow meter.

In this article we explain why installing any MCERTS flow measurement system requires a holistic approach, and the importance of consulting the experts to ensure your system is not only cost-effective but fit for purpose.

“Why do I need to look at the whole system? I just need a flow meter.”

It’s something we hear often. A customer already has a legacy system in place and just wants to replace a small part of it. The problem is, it’s not always that easy.

Over the years our servicing and installation engineers have seen hundreds (if not thousands!) of flow measurement systems, and a surprising number of them simply aren’t fit for purpose – and likely never have been.

While we could just sell you the component you ask for, there’s no guarantee that it will be suitable for your existing system – and more importantly, no guarantee it will pass an MCERTS inspection. Ultimately, making the wrong choices can end up being a very costly mistake for your business.

How MCERTS flow measurement experts can help

We ask the right questions

There are several key questions we need to consider when installing part, or all, of an MCERTS flow measurement system:

- Is the component suitable for the existing system? Understanding the type of flow measurement system is essential to choosing the right components. For example, a state-of-the-art electromagnetic flowmeter might sound like the best choice, but it’s not going to be very useful fitted in to an open channel drain or close to an aeration treatment plant and thus effected by entrained air.

- Can the system be calibrated and future-proofed? If the existing system has been incorrectly installed from the start, new part isn’t going to solve the problem and we can’t effectively validate the system.

- What is the nature of the discharge? We often get asked for a specific type of flow measurement, for example a V notch weir. However that isn’t a very effective method if the discharge contains significant solid content and can blind the V.

- How has the flow measurement system been maintained? Poorly maintained equipment is one of the most common issues we encounter when visiting sites and is a leading cause of incorrect readings.

- Is the flow measurement system suitable for your site? There is no one-size-fits-all solution when it comes to flow measurement. It’s essential to get a thorough understanding of the site the system is for to ensure it is fit for purpose. Factors such as available space, flow volumes and permit conditions are all important considerations.

We make sure your system is correctly calibrated

Regular flow meter calibration is essential for ensuring your device continues to provide accurate results. Not carrying out this vital process can result in your flow meter recording incorrect data and could result in a failed MCERTS inspection, or incorrect charging from your water utility provider.

When we install a new flow measurement system we always ensure it has been correctly calibrated. We also ensure that any flow measurement system we install has been designed to allow for future in-the-field calibration.

We guarantee MCERTS compliance

Choosing an MCERTS-accredited product doesn’t mean the flow system will automatically pass an MCERTS inspection.

We guarantee that any system we design, install, and maintain will be fully MCERTS-compliant – giving you the peace of mind that your system is providing accurate, cost-effective results and ensuring ongoing compliance with Environment Agency regulations.

We ensure the right data monitoring is in place

Data monitoring allows you to gather crucial flow meter data and ensure you are satisfying regulatory compliance for your water authority, as well as environment agencies in both England and Scotland.

Our cloud-based system offers a robust and reliable ‘plug-in and play’ option for wastewater flow monitoring using a specialist remote telemetry unit (RTU) and data visualisation suite, Palette.

Our bespoke Palette system allows you to monitor your effluent discharge from anywhere, at any time. Our cloud-based software gives you 24/7 access to your data, giving you the ability to get the information you need, whenever you need it.

WE CAN HELP

For any queries or assistance with your flow measurement system, please contact our expert installations project team who will be able to offer you advice and support on choosing the right system for your site.