Use of Contact and Non-Contact EDMs (Event Duration Monitors)

michael mc

on

April 27, 2023

The subject of Event Duration Monitoring has gained prominence over the last few years, with water companies investing in new and improved monitoring in response to changing legislative requirements – often referred to as U_MON3.

Working to support our clients with event duration monitoring is just one of our daily services – and one of the questions we are often asked is why contact EDM solutions are not our first choice or preference.

Given the often inexpensive outlay and historic role in the industry, they can appear an attractive choice. However, there are a number of issues when using contact EDM devices that can impact both the accuracy and consistency of the data, as well as the ongoing operation of the device itself.

In this article, we explain the typical shortfalls seen with contact probes and how EDM systems can be better built to ensure reliable data is provided to the regulator.

What is Event Duration Monitoring?

An “event” in the world of flow measurement means an “adverse weather event” (most commonly a storm), which has the impact of increasing flow through a Sewage Treatment Works (STW).

All STWs have a maximum limit of flow that they are permitted to treat. This is known as Flow to Full Treatment (FFT) or Flow Pass Forward (FPF). If the flow within an STW exceeds this limit during a storm event then it is allowed to overflow into a storm management system and/or discharge straight into a river.

However, there are instances where an STW may discharge to a storm management system/river before the maximum limit is reached, or even for a reason not related to a storm event – for example, as the population and communities that they serve grow, STWs may increasingly find excess demand on their original flow capacities – risking more frequent breaches of their permitted FFT.

Event Duration Monitoring (EDM) enables the water utility provider to keep a reliable record of all instances of overflows spilling. Combined with other data (such as weather conditions and the volume of flow going forward to treatment at the time of the event), this can be presented to the regulator as evidence of a storm event being within the site’s permit condition. If it is outside the permit condition, then the water utility provider has the benefit of better quality data to make changes to the site and prevent further early spills.

In 2018, the Environment Agency announced a series of measures designed to better monitor Flow to Full Treatment, which included the requirement for water companies to install EDM monitoring by 2025. The Government also announced further measures to ensure STWs are not relying on storm overflows outside of storm events.

Fluid Contact or Non-Contact Probes for EDM?

Any EDM system used at an STW or pumping station must be able to accurately recognise when an overflow is taking place and an “event” is being triggered.

The vast majority of typical Event Duration Monitors can be classified as either contact or non-contact (which can use an ultrasonic or radar sensor.)

The Event Duration Monitor’s job is simply to record an “event” when the fluid level begins to pass to storm management overflow, typically over a storm overspill weir. The setting of the “event” requires precise calibration and adjustment in terms of both the physical installation and the the Event Duration Monitor’s programmed settings.

How a Contact EDM Works

A contact EDM typically consists of two probes that provide a switched status output to an external system when the fluid level reaches the overflow point.

Issues When Using Contact Probes for EDM

It is difficult to set the probes to the required uncertainty level of +/- 5mm

Often on sewage treatment works it is physically difficult to set the probes to the required ±5mm uncertainty level, which could likely result in a confined space entry and/or isolation of a live sewer channel. The use of a non-contact EDM device eliminates these safety risks.

Contact Probes are Susceptible to Damage in this Application

The nature of wastewater flow means that objects in the stream can hit and damage the probes, potentially bending them so that they are no longer correctly positioned.

False alarms can also be triggered by objects such as rags becoming entangled in the probes.

Calibration is not Possible

It is difficult to find any reliable reference point for the calibration of the system given the way it is set up, bringing doubts to the accuracy and reliability of the data during analysis and inspections.

Furthermore, any checks of of a system using contact probes would require a live event to be triggered, meaning effluent water would be discharged into the overflow system/river.

The verification of an EDM system using contact probes typically also means entering a confined space and creating a more dangerous environment for those working. HSE dictates within the hierarchy of safety that this risk should be removed if possible.

How a Non-Contact EDM Works

Non-contact EDMs are mounted above a channel or wet well – without any contact to the fluid being measured. The two main types of non-contact EDMs used on the market are ultra-sonic or radar. Although different technologies, they both operate by sending a signal down to the fluid, which then reflects back to the sensor.

By knowing the distance to the fluid these devices can then accurately determine the fluid depth at any given moment.

Advantages of a Non-Contact EDM

Easy to Install

Non Contact EDM sensors can be installed above the channel or wet well with a clear view of the fluid or flow. There is often no need to then enter the channel to set-up or reference.

Low Maintenance

Given the non-contact nature of the probe, it is not susceptible to the risk of damage or fouling from objects and debris, as with contact-type probes.

Easy to Calibrate

Following initial installation, non-Contact EDMs are easy and safe to validate through accurate pre-set reference points.

In the vast majority of cases everything can be done without the need to enter a confined space or live sewer channel/wet well. A calibration certificate can then be provided.

Non Contact EDMs can follow the same proven methodology as calibration used for regulatory open channel flow measurement flumes and weirs.

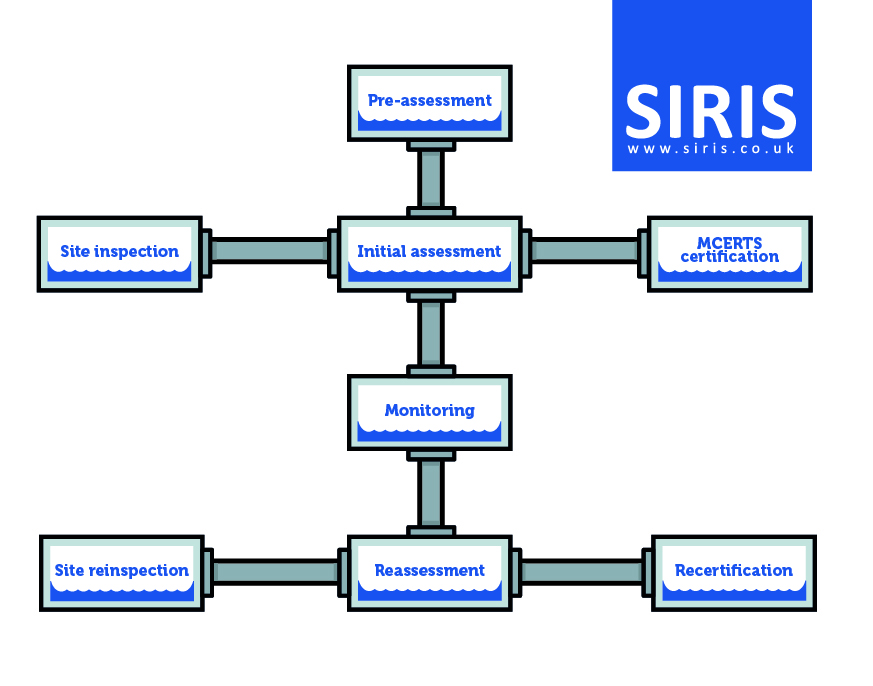

How We Can Help with Event Duration Monitoring

Our team is experienced in all scenarios of EDM system implementation, calibration and ongoing support.