Sitrans Mag 6000 Manual (FM MAG 5000/6000) Operating Instructions

Download the Sitrans MAG 6000 manual.

siris2021

on

June 28, 2022

Download the Sitrans MAG 6000 manual.

siris2021

on

May 3, 2022

Offering a flexible and reliable water flow meter, the SITRANS FM MAG 8000 battery-operated water meter is suitable for a variety of locations without compromising on accuracy or performance.

Flexible installation – IP68 (NEMA 6P) compliance allows installation in soil or underwater

Low pressure loss and excellent leak detection

Maximum freedom in installations with low inlet and outlet distances

Approved for MID-001 without defined length of inlet and outlet

Remote access possible – running flow data through optional wireless 3G / UMTS communication module

The Sitrans Mag 8000 Flow Meter is packed full of features and innovations for optimum performance.

The Siemens product offers accessible data

For enquiries about this flow meter or any elements of flow meter systems please contact our expert team

siris2021

on

April 25, 2022

Wastewater sampling: what is measured and why?

The majority of businesses producing wastewater are required to carry out wastewater sampling to comply with their permit requirements.

Often this will be via self-monitoring, however companies may find themselves the subject of spot checks of their samples by the local water company to ascertain composition and volume of trade effluent produced. This supplied information is important as water companies use it to calculate final water treatment costs, using a method known as The Mogden Formula.

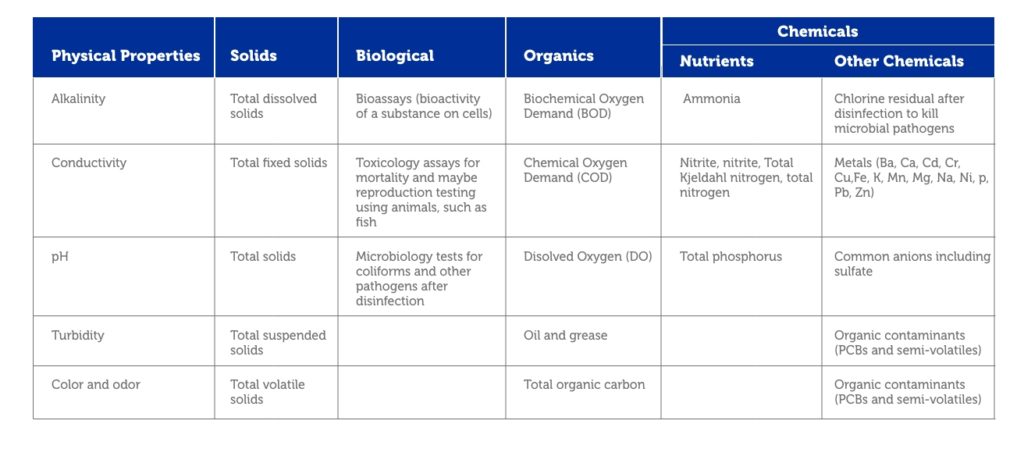

What is being measured?

The full spectrum of analytes covered by MCERTS is listed in the Environment Agency standard Performance Standard for Organisations Undertaking Sampling and Chemical Testing of Water.

This is the standard businesses should refer to when implementing their effluent sampling processes as it details business requirements for the sampling and testing of trade effluent.

Physical properties analysed during wastewater testing include:

Dissolved oxygen (DO) in water is essential to the survival of aquatic life.

In wastewater sampling, the BOD (biochemical oxygen demand) and COD (chemical oxygen demand) of effluent are measured to ensure water course DO levels will not be impacted by its discharge.

BOD measures the biological oxygen demand over a five-day period and equals the amount of dissolved oxygen required by organisms for aerobic decomposition of organic matter present in the water.

COD refers to the mass concentration of oxygen equivalent to a specified oxidant consumed by dissolved or suspended matter when a water sample is treated with that oxidant under defined conditions.

The level of solids in wastewater affect its quality and how it needs to be treated going forward.

Solids measurement differs from turbidity in that TSS measures the actual physical particles in the water (e.g. sediment) whereas turbidity measures the effect on light caused by particles. Solid measurement is split into:

An excess of nutrients in water contributes to algae overgrowth.

Nutrient measurement is important as too much algae in water uses high amounts of nitrogen and phosphorus and results in the production of neurotoxins that are harmful to animals and may contaminate future drinking water.

Typically measured nutrients include:

Trade effluent from industrial processes is a primary source of heavy metal contamination.

Industries including textile, paper/pulp and metal finishing are all contributors, producing effluent that contains the “top four” toxic heavy metals arsenic (metalloid), cadmium, lead and mercury as well as chromium, nickel and zinc which are also toxic to humans and animals.

Next steps

The above list is not exhaustive, but contains some of the common analytes permit holders are required to be measured on. It may seem like an overwhelming task, but a good automatic wastewater sampler and associated monitors provide an accurate and user-friendly solution.

SIRIS offer a comprehensive range of MCERTS-approved wastewater samplers and analytical measurement tools designed to simplify the wastewater analysis process.

For any queries or assistance with your trade effluent sampling or flow measurement, please contact our expert installations project team, who are set to help with any effluent challenge.

siris2021

on

April 7, 2022

Calculating Trade Effluent Charges

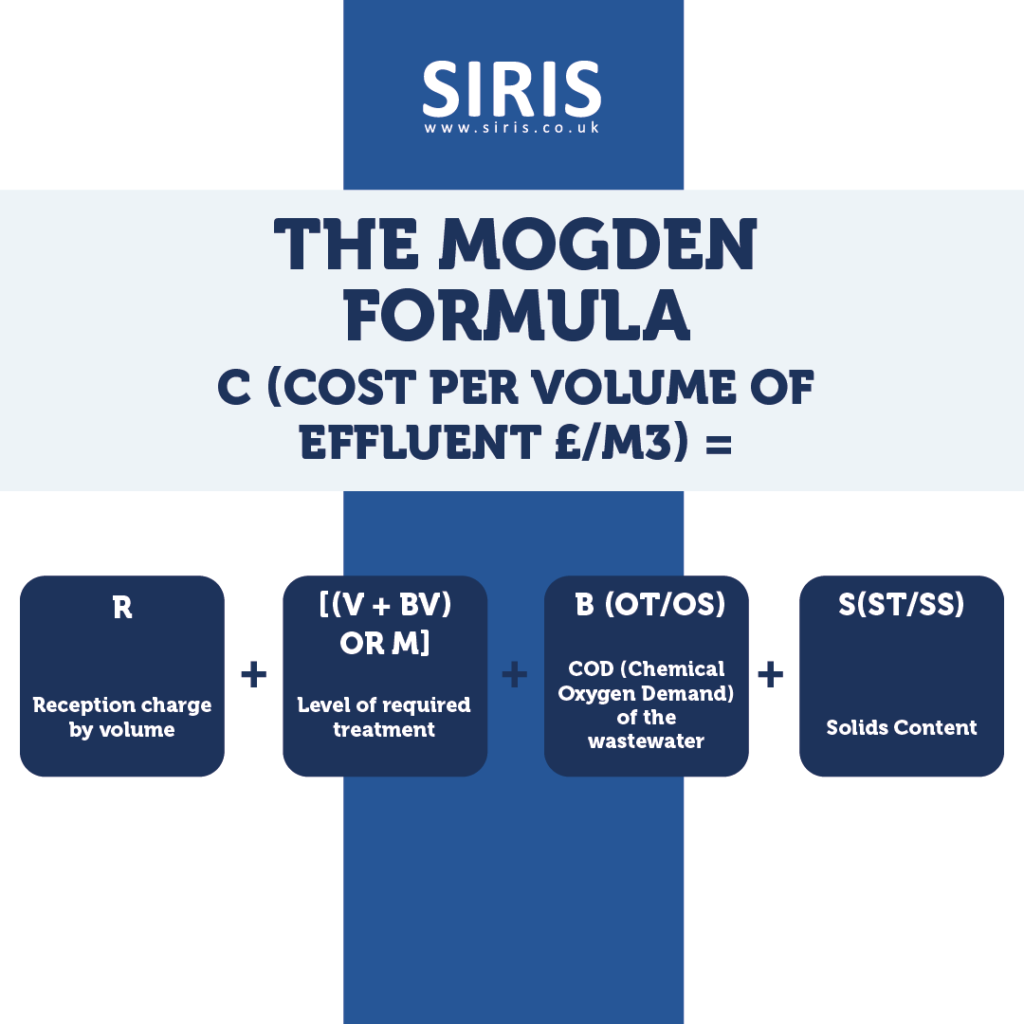

This rather complex-looking equation represents the key tool in calculating trade effluent charges. Termed The Mogden Formula after first being adopted at the Mogden Water Works in London, it incorporates a number of variables such as contaminant and suspended solids levels that are used to calculate the final treatment cost per m3 of the effluent.

The formula can be broken down as follows:

R = the charge from the water treatment works for receiving and conveying the effluent (in £/m3)

V = the charge from the water treatment works for the primary treatment* of the effluent *removal of material that will either float or readily settle out by gravity

(in £/m3)

Bv = the charge from the water treatment works for any biological* treatment (in £/m3) *breakdown/decomposition of organic contaminants from the wastewater

M = the charge from the water treatment works for the treatment and disposal of any effluent that must go out to sea (in £/m3)

B = the charge from the water treatment works for the biological oxidation* of any settled sewage (in £/m3) *B-stage, or bio-oxidation stage, where remaining organic material in low-loaded activated sludge is biodegraded

Ot = the chemical oxygen demand (COD) of effluent after one hour of quiescent settlement at pH 7 [mg/litre]

Os = the chemical oxygen demand (COD) of effluent after one hour of quiescent settlement [mg/litre]

S = the charge from the water treatment works for the treatment and disposal of the primary sewage sludge (in £/kg)

St = the total of suspended solids of effluent at pH7 (in mg/litre)

Ss = the total of suspended solids of effluent (in mg/litre)

The more contaminants and suspended solids in the wastewater or effluent, the more expensive it will be to treat and dispose of. This is known as The Trade Effluent Charge and is charged by the local water company to cover costs associated with the transportation, treatment and disposal of the effluent.

Many companies use water as part of their processing, such as produce cleaning or cooling, and understanding your Mogden formula can help identify areas to reduce wastewater processing charges. Essentially there are two ways to do this:

– Reduce the levels of contaminants/solids within the effluent

– Reduce the volume of effluent

Water companies will issue licences of “Consent to discharge trade effluent” to those companies producing effluent for public disposal, which will outline specific conditions and charges for your licence. The consent licence will stipulate how the wastewater must be monitored (or measured). Sometimes this will be through self-monitoring but the water company may also routinely monitor flow and composition of the effluent to ensure compliance and estimate charges. Water companies may vary in their application of the Mogden formula, but this information will be publicly displayed on their website, in line with the OFWAT regulator.

Having an accurate and reliable picture of your effluent data is therefore key in ensuring the correct charges are being paid, as well as understanding where costs are coming from within the variables. This is done via two primary methods – wastewater sampling and wastewater flow measurement.

An accurate base for calculations

Effluent sampling ensures the accurate measurement of those variables used within the Mogden formula. Without them, calculations may be based on estimates, which could be bringing unnecessary additional charges to the business.

Investing in an approved, on-site wastewater sampling system gives more comprehensive and ongoing accurate data that can be used to monitor the quality of the wastewater discharge on a continual basis, using composite samples to provide data to the EA and local water authorities that can reduce charge liabilities and business costs.

At SIRIS we offer a range of MCERTS-accredited wastewater samplers that suit both open channel and closed pipe applications, providing robust and long-lasting sampling solutions for a range of industrial and commercial businesses. We offer automatic, composite, refrigerated sampling, which ensures regular samples of your effluent at key times e.g. high loads/low loads. Factors such as this are important and carefully considered in the design and specification of your effluent monitoring system by the SIRIS team. For example, water company spot samples may focus on times of high contaminant concentration, giving an inaccurate picture of the average effluent strength level and causing unnecessary charges. The refrigerated element of our samplers ensures that samples do not degrade.,

Ensure a true picture of volume of effluent

Measurement of volume of flow is another critical data point in which to ensure accuracy. Again, on-the-spot water company measurements can give biased flow volumes, for example if these were taken only during high production points on the plant.

Our solutions ensure an accurate picture of flow volume over time. Depending on the specific business type and requirements, effluent flow may be measured on either an instantaneous or continuous basis, each of which requires careful specification of equipment. At SIRIS, our experienced approach to effluent flow measurement allows us to specify and develop robust and reliable measurement systems.

For any queries or assistance with your trade effluent sampling or flow measurement, please contact our expert installations project team, who are set to help with any effluent challenge.

siris2021

on

March 5, 2022

The whole projects team at SIRIS is proud to have been a recognised supply chain partner in the award-winning Wolsingham Sewage Treatment Works (STW) Growth Improvement Project. Completed in 2021 during the height of the pandemic, the £6m project has been awarded Civils Project of the Year in the Constructing Excellence in the North East Awards.

Led by Tilbury Douglas (contractor) and Wood (designer) for client Northumbrian Water, the project was recognised for its use of new technology, implementation of off-site, sustainable construction methods and best-in-class collaboration between all project stakeholders

An upgrade to tackle increased flows and asset deterioration

The Sewage Treatment Works was in need of an upgrade as demand on the site had increased in line with population growth in the area, estimated at some 19%. The upgrade project had to identify solutions to the issues caused by increased flows and loads identified at the site and the related impacts on associated sewerage networks. In addition to this, further work to tackle asset deterioration and ongoing pollution incidents due to sewer overflow was to be incorporated into the project.

The design phase of the project, started in 2018, took an innovative “Off-site by Default” and DfMA (Design for Manufacture and Assembly) approach to build technology, an ethos that was mirrored throughout all phases of the project with the ongoing support of client Northumbrian Water. The Sewage Treatment Works was consequently able to be built using off-site build methodology, a ground-breaking approach within the water industry.

This method brought tangible and sizeable benefits to the project in terms of reduced costs, timelines and environmental impact; with some £1m pounds, 4 months and 34 man hours estimated to have been removed from the project initial budgets and timescales.

Northumbrian Water now plans to adopt the new off-site build approach within their AMP7 framework, a real testament to the success of the project and the collaboration of partners and supply chain throughout.

Off-site Build Concepts

Working under the brief of design partners, Wood, SIRIS was able to develop off-site build concepts for the inlet of the works, using a prefabricated, above-ground approach. The inlet-flume design was built offsite within the SIRIS on-site factory, using non-standard GRP-reinforced, welded PVE construction materials to give the increased accuracy and sensitive tolerances expected for MCERTS certification. The materials also benefited from a service life of up to 50 years.

Transported in two sections, the inlet flume was installed readily into the SWT without problem, showing the potential for future off-site build methods for installations of this type.

“The off-site construction nature of this project represented a new approach in the water industry. With our on-site factory and engineering team, we were able to quickly integrate into the adopted working methods by providing a fully constructed inlet flume and weir system, then transported to and installed on the works site directly. Our team collaborated fearlessly with the project team to achieve all requirements and we are proud to have been involved in such an innovative development.”

siris2021

on

July 9, 2020

Effluent flow meters are designed to accurately measure the rate of flow of wastewater within a particular operating environment. Most UK businesses subject to consent to discharge permit requirements will be required to record and submit the volume and quality of the wastewater they are producing – and will require a wastewater flow meter of some description for this purpose.

There are various types of meter available, covering both open and closed channel and clean or dirty water. If the responsibility for effluent flow measurement is yours, then it is important that you understand why certain flow meters should be used in particular conditions.

This guide to types of flow meters explains the different types of effluent flow meters that are available and what to consider when both selecting and maintaining your flow measurement solution.

Effluent flow meters are typically split for suitability for either open channels or closed pipes.

Within open channel flow, the top surface of the water is usually open to the atmosphere. Examples of open flow are streams, flumes, rivers, drains and ditches. The flow can be steady or unsteady.

The flow in open channels typically occurs due to gravity, and the maximum velocity occurs a short distance below the water surface, with the HGL (Hydraulic Grade Line) coinciding with the water surface line. A cross section of an open channel will usually be triangular, rectangular, circular or trapezoidal and factors influencing flow in open channels include channel shape, fluid velocity and depth and the slope of the channel.

Open channel ultrasonic flow meters provide a reliable and accurate method of measurement in these open conditions, used as part of an open channel flow measurement system and should be used alongside a “primary flow device” such as a flume or a weir.

The typical methodology for measuring flow in an open channel is to measure the depth of the liquid in the channel using the ultrasonic sensor while it flows through the weir or a flume, before the flow meter then uses this depth to calculate the flow rate. This method relies on the flumes or weirs being constructed and installed in a manner that ensures the water depth at the point of measurement (the gauge point) is smooth and controlled.

The ultrasonic flow meter transmits continuous high-frequency sound pulses, waiting for an “echo” to determine the exact depth of the water upstream the flume or weir.

The exact variation of formula used to then calculate the flow will differ depending on the specific primary flow device used.

Key factors:

Area velocity flow meters calculate flow rate by understanding the cross section and nature of the channel in which it is measuring depth and velocity. There are two types of this flow meter: non-contact and wetted. The wetted version is often placed on the bed of a channel and has historically used the doppler effect to measure the velocity. Non-contact types are mounted above the channel and beam a radar (surface velocity only) or laser (surface and sub-surface velocities) to measure the velocity, with the depth often calculated using a look-down ultrasonic sensor. An area velocity flow meter for effluent water operates on the area x velocity method to calculate flow rate. This shift in frequency is used to provide a flow velocity measurement.

Key Factors:

Closed pipes, such as those used for the transportation of effluent flow, are able to use effluent flow meters which calculate flow by already understanding the cross section of the pipe being measured. This process is dependent on the pipe being fully flooded so that the “area” of the cross section being measured is known. Provided there is confidence in a fully developed flow profile, then the meter only needs to use sensors to measure velocity. However, the flow profile can be impacted by things such as bends, gates and twists in the pipe so it is essential that it is installed by a professional to ensure these are accounted for and the flow profile is known.

Designed for measuring liquid flow within an enclosed pipe, electromagnetic flow meters measure the voltage produced by a conductor (the wastewater) moving through a magnetic field. The voltage is proportional to the velocity of the conductor and can be converted to a flow rate. This calculation works on the principle of Faraday’s Law of electromagnetic conduction. Also commonly known as “magmeters”, they require a conducting fluid such (in this instance effluent) and a non-conducting pipe liner. These meters are popular and provide a highly accurate option for wastewater flow measurement and all SIRIS electromagnetic flow meters satisfy the necessary regulatory requirements.

Key factors:

A clamp-on ultrasonic flow meter is a convenient method for flow measurement as they do not require the pipe to be opened up for their installation.

They work using the “transit time” theory, where the difference in transit time between those pulses going in the direction of flow, versus those going against the direction of flow is measured. This measurement of difference is then used to give the liquid average velocity along the path of the ultrasonic pulse. Using these transit times and knowing the area of the pipe it is possible to measure flow rate.

These units are also available for hire and can provide a temporary flow measurement solution.

Key factors:

Any consent to discharge permit will require correct installation, operation and maintenance of your flow measurement system.

Careful and knowledgeable selection of measurement system is important as each flow meter type varies in its suitability depending on:

Correct and regular calibration of any flow meter is fundamental to confirm accuracy of data. In an ideal world a flow meter would never be affected by the conditions in which it is installed, however aggressive environments and other factors can compromise their initial installation. There is also the chance that an old system may never have been installed properly in the first instance. Although no flow measurement system is 100% accurate, with all carrying some level of uncertainty, correct calibration and robust maintenance can ensure that this level is kept to a minimum.

If you are required to install a flow meter as part of your permit or consent to discharge then it is your responsibility to ensure its correct functioning and data accuracy. Failure to confirm this could lead to penalties and fines. It is always worth the investment in a professional and informed approach from an experienced MCERTS-qualified team to guarantee long-term value for money from your flow measurement system. Not only can they ensure correct set-up, inspection and calibration, but they can also provide also provide ongoing support and guidance for when things go wrong.

Get in touch with our expert team to discuss your flow measurement requirements.