LEARN MORE ABOUT:

The Mogden Formula

Calculating Trade Effluent Charges

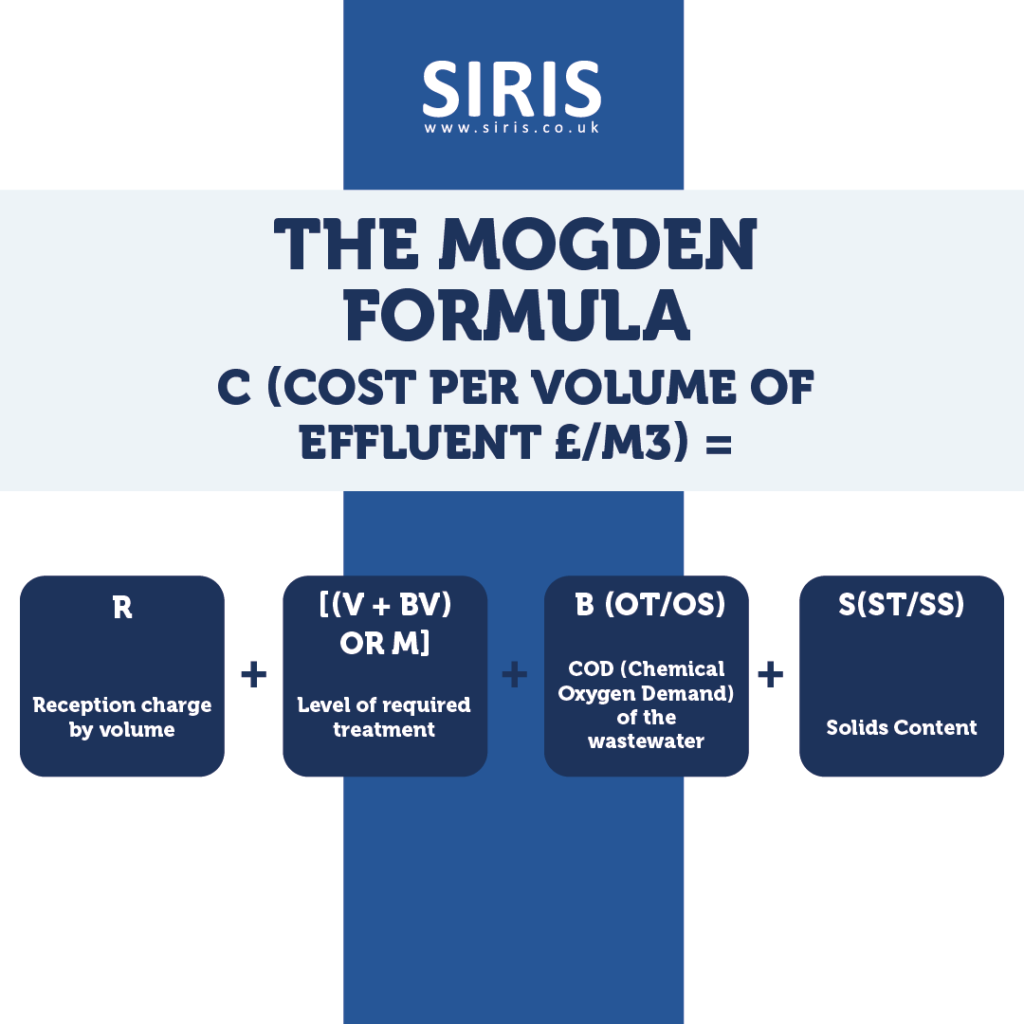

This rather complex-looking equation represents the key tool in calculating trade effluent charges. Termed The Mogden Formula after first being adopted at the Mogden Water Works in London, it incorporates a number of variables such as contaminant and suspended solids levels that are used to calculate the final treatment cost per m3 of the effluent.

The formula can be broken down as follows:

R = the charge from the water treatment works for receiving and conveying the effluent (in £/m3)

V = the charge from the water treatment works for the primary treatment* of the effluent *removal of material that will either float or readily settle out by gravity

(in £/m3)

Bv = the charge from the water treatment works for any biological* treatment (in £/m3) *breakdown/decomposition of organic contaminants from the wastewater

M = the charge from the water treatment works for the treatment and disposal of any effluent that must go out to sea (in £/m3)

B = the charge from the water treatment works for the biological oxidation* of any settled sewage (in £/m3) *B-stage, or bio-oxidation stage, where remaining organic material in low-loaded activated sludge is biodegraded

Ot = the chemical oxygen demand (COD) of effluent after one hour of quiescent settlement at pH 7 [mg/litre]

Os = the chemical oxygen demand (COD) of effluent after one hour of quiescent settlement [mg/litre]

S = the charge from the water treatment works for the treatment and disposal of the primary sewage sludge (in £/kg)

St = the total of suspended solids of effluent at pH7 (in mg/litre)

Ss = the total of suspended solids of effluent (in mg/litre)

The more contaminants and suspended solids in the wastewater or effluent, the more expensive it will be to treat and dispose of. This is known as The Trade Effluent Charge and is charged by the local water company to cover costs associated with the transportation, treatment and disposal of the effluent.

Many companies use water as part of their processing, such as produce cleaning or cooling, and understanding your Mogden formula can help identify areas to reduce wastewater processing charges. Essentially there are two ways to do this:

– Reduce the levels of contaminants/solids within the effluent

– Reduce the volume of effluent

Water companies will issue licences of “Consent to discharge trade effluent” to those companies producing effluent for public disposal, which will outline specific conditions and charges for your licence. The consent licence will stipulate how the wastewater must be monitored (or measured). Sometimes this will be through self-monitoring but the water company may also routinely monitor flow and composition of the effluent to ensure compliance and estimate charges. Water companies may vary in their application of the Mogden formula, but this information will be publicly displayed on their website, in line with the OFWAT regulator.

Having an accurate and reliable picture of your effluent data is therefore key in ensuring the correct charges are being paid, as well as understanding where costs are coming from within the variables. This is done via two primary methods – wastewater sampling and wastewater flow measurement.

THE MOGDEN FORMULA IN PRACTICE

Role of Effluent Sampling

An accurate base for calculations

Effluent sampling ensures the accurate measurement of those variables used within the Mogden formula. Without them, calculations may be based on estimates, which could be bringing unnecessary additional charges to the business.

Investing in an approved, on-site wastewater sampling system gives more comprehensive and ongoing accurate data that can be used to monitor the quality of the wastewater discharge on a continual basis, using composite samples to provide data to the EA and local water authorities that can reduce charge liabilities and business costs.

At SIRIS we offer a range of MCERTS-accredited wastewater samplers that suit both open channel and closed pipe applications, providing robust and long-lasting sampling solutions for a range of industrial and commercial businesses. We offer automatic, composite, refrigerated sampling, which ensures regular samples of your effluent at key times e.g. high loads/low loads. Factors such as this are important and carefully considered in the design and specification of your effluent monitoring system by the SIRIS team. For example, water company spot samples may focus on times of high contaminant concentration, giving an inaccurate picture of the average effluent strength level and causing unnecessary charges. The refrigerated element of our samplers ensures that samples do not degrade.,

ACCURATE VOLUME OF FLOW

Role of Flow Measurement

Ensure a true picture of volume of effluent

Measurement of volume of flow is another critical data point in which to ensure accuracy. Again, on-the-spot water company measurements can give biased flow volumes, for example if these were taken only during high production points on the plant.

Our solutions ensure an accurate picture of flow volume over time. Depending on the specific business type and requirements, effluent flow may be measured on either an instantaneous or continuous basis, each of which requires careful specification of equipment. At SIRIS, our experienced approach to effluent flow measurement allows us to specify and develop robust and reliable measurement systems.

WE CAN HELP

For any queries or assistance with your trade effluent sampling or flow measurement, please contact our expert installations project team, who are set to help with any effluent challenge.