SIRIS supports Yorkshire Water and BarhaleDoosan JV in trial of first nature-based wastewater treatment plant.

michael mc

on

January 31, 2022

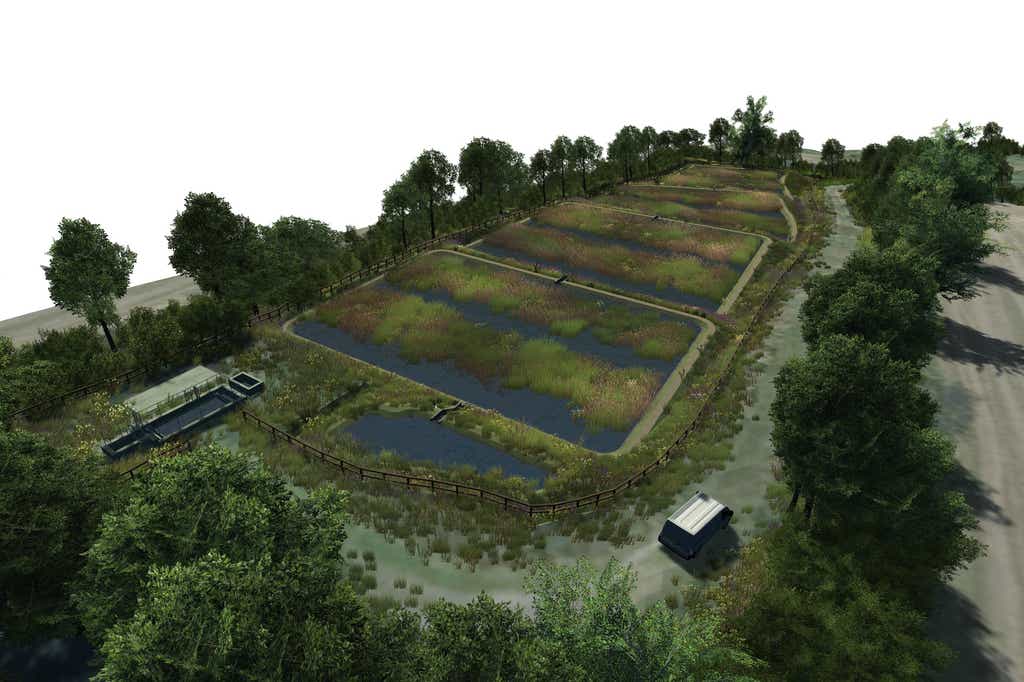

A trial of a sustainable wastewater treatment system is underway at the Yorkshire Water Clifton works, where over 20,000 wetland plants utilising the natural clay are being used to remove phosphorous from the wastewater as a natural alternative to traditional, energy-heavy chemical treatment.

The successful trial of the project will pave the way for further low-carbon, sustainable clay and wetland treatment plants, which aim to reduce energy and chemical usage, as well as create wildlife diversity including bees, breeding birds, amphibians and reptiles.

Further sites have already been identified across the Yorkshire region and results will be closely monitored for potential roll-out.

Flow Monitoring Solutions Provided by SIRIS

Working alongside design partner Stantec, BarhaleDoosan JV was the project partner tasked with construction of the site and engaged SIRIS to provide monitoring solutions to deliver key data on the flow of wastewater through the plant.

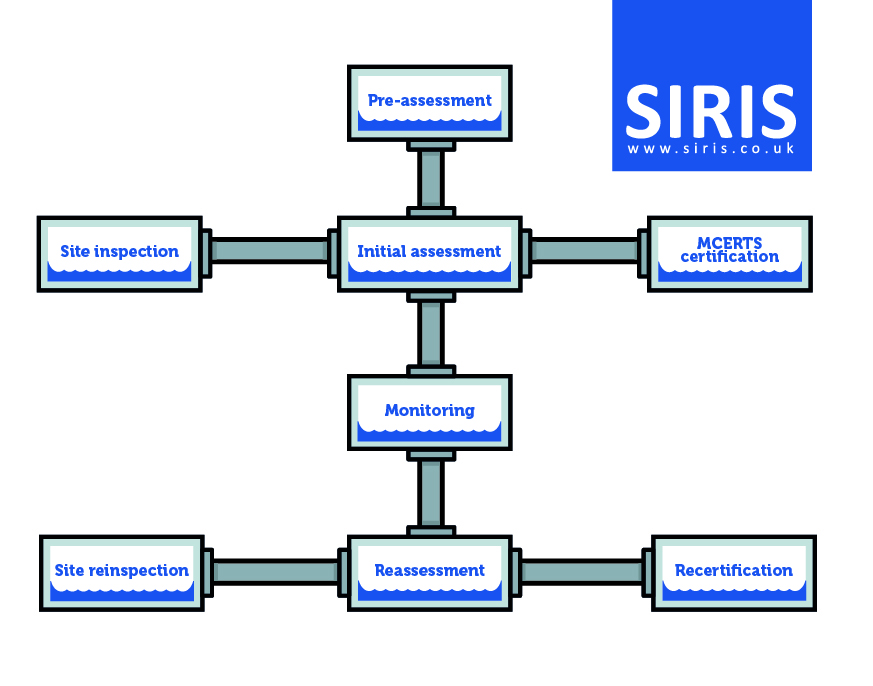

With the trial being closely monitored by both project partners and the Environmental Agency, the MCERTS-approved, wastewater flowmeters are providing important data to gauge wastewater evaporation and flow leakage rates between inlet and outlet points at each end of the 5x 800m3 plant cells. The flow meter system includes a battery powered cloud-based telemetry, meaning information is accessible for project stakeholders.

A high level of evaporation or flow leakage would mean that plants within the marshland would not receive the required nutrients required for their long-term survival and lead to unacceptable levels of phosphorous and BOD in the final wastewater output.

Important to the project for BarhaleDoosan JV was to maintain a low carbon footprint across the whole project, including design and build processes. The easy-to-maintain open channel flow meters were designed to include a solar panel, which not only makes them highly energy-efficient, but removed the need for installation of over 200m of cable ducts and electric cables, concrete-heavy draw pits and associated deliveries of materials.

The level of support from the team at SIRIS was outstanding. They were very approachable, knowledgeable and fully engaged when considering all options to meet our project aims, coming back with well-thought-out and cost-efficient solutions.”

The team at SIRIS is also excited to see the results from the trial. General Manager Karl Bambynek said,

“The project is a milestone in bringing sustainability within the wastewater treatment industry and we are proud to be involved in its delivery. If successful we could see significant roll-out and an important positive impact on the environment and its levels of biodiversity. We are pleased that our flowmeter systems can play a part and look forward to following the project’s progress.”