Siris Weir Plates For Effluent Flow Monitoring

At SIRIS, we provide a range of weir plates for varying applications and environmental circumstances. Your choice of weir plate will depend on your individual set-up and requirements. In this guide, we explain factors to consider in weir plate choice for your flow monitoring installation.

What is a Weir Plate?

A weir plate is a thin barrier used within flow monitoring installations in open channel conditions. Its purpose is to restrict the flow, thus creating the correct conditions to allow for accurate measurement of the flow rate using the head (or height of Hmax) of the liquid upstream of the weir plate. Flow rate measurements are then typically taken using a flow meter sensor positioned above the head of the flow (often known as the gauging point).

You can learn more about how weir plates work here.

When designed, installed and maintained correctly, thin plate weirs provide a highly accurate solution within open channel flow measurement.

Types Of Weir Plate

Weir plates can be found in popular shapes such as rectangular, trapezoidal, compound of V-notch shapes. At SIRIS we carry both V-notch and rectangular weir plate designs in stock but we can also supply compound weirs for bespoke projects.

V-Notch Weir Plates

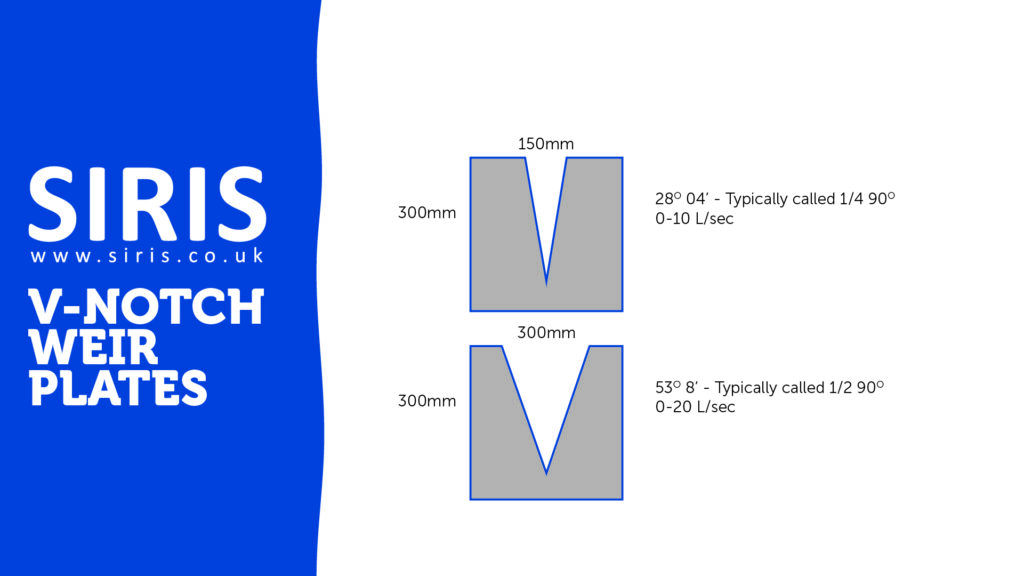

At SIRIS, we offer V-notch weir plates in notch angle sizes of 28° (typically known as 1/4 90°) or 53° (typically known as 1/2 90°). The lower the flow then the narrower the notch width should be to create the restriction needed to give optimum conditions for measurement at the head.

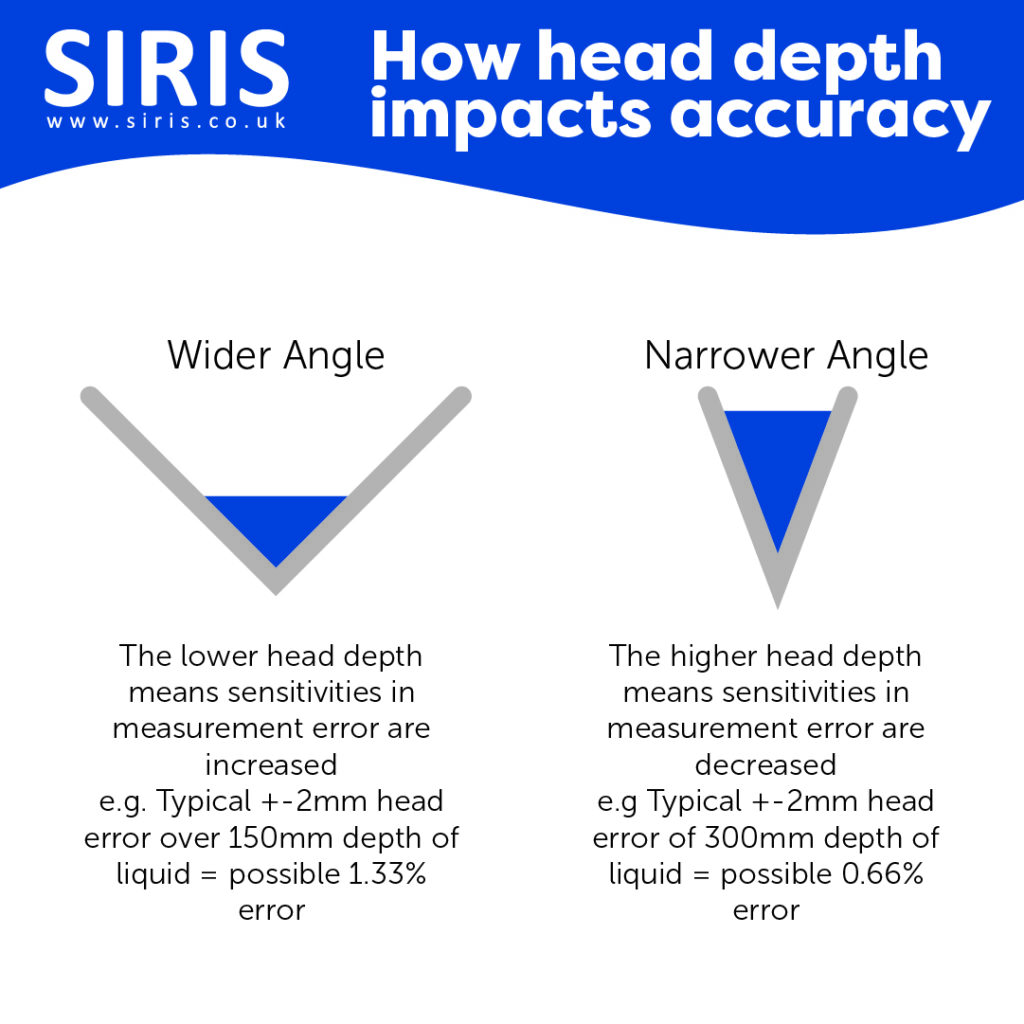

V-notch weirs are typically more suitable for lower flow rates as they provide greater accuracy in these conditions. We can see an example of how this works below, in that the narrower notch width increases the head and therefore any margin of error in measurement of head height is proportionately less.

Rectangular Weir Plates

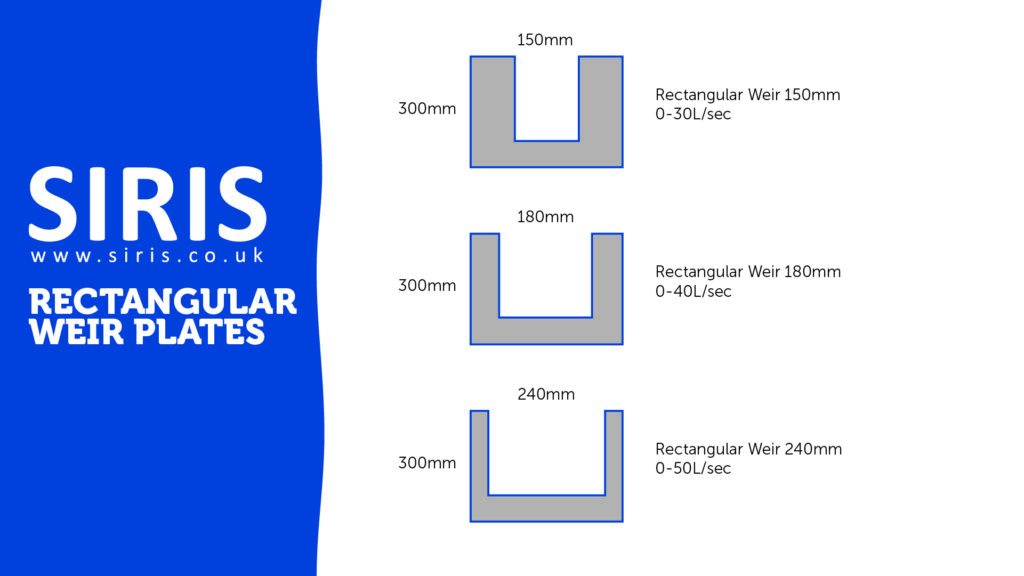

At Siris, we offer a number of sizes for rectangular weir plates.

Better with higher flow rates

Require less approach

One clear advantage of the rectangular weir plate is the reduction in approach needed for accurate measurement. For all weir plates, the approach should be 10x the width of top of the weir notch (or nappe). As rectangular weirs let through a larger volume of water than a V-notch, the measurement at the top of the nappe is less than for a V-notch weir, even at the same flow requirements. This then has a proportional effect on the length of approach needed.

For example, at 40 Vs the measurement of the top of the nappe would be 180mm, meaning an approach of 1.8m would be needed. For the same flow rate a 90° V-notch weir plate would need an approach of 4.8m as the nappe would be 483mm. At the same flow rate, a 1/2 90° would still require an approach of 3.2m (with a nappe measurement of 320mm).*

*Illustrative purposes only, a half 90° would not be used in such high flow conditions.

Less risk with debris

Choice of Weir Plate

If you know the flow rate and size of your channel, then this is the key information needed for weir plate choice. However, set-up can get more complex, depending on installation conditions and whether a chamber/baffle/weir tank, etc. is in place. Upstream and downstream conditions are also key, as is required approach and conditions within.